Work Volume Of Scara Robot

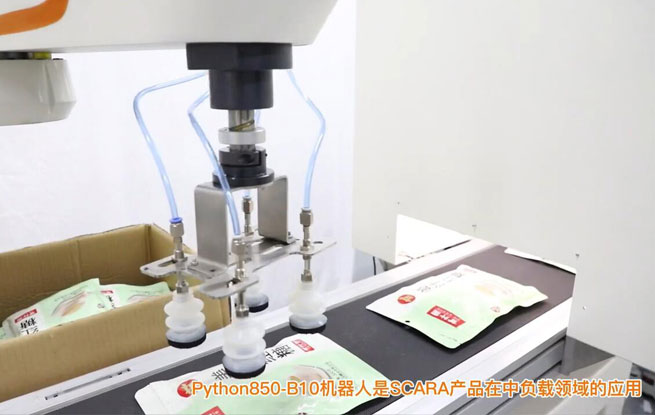

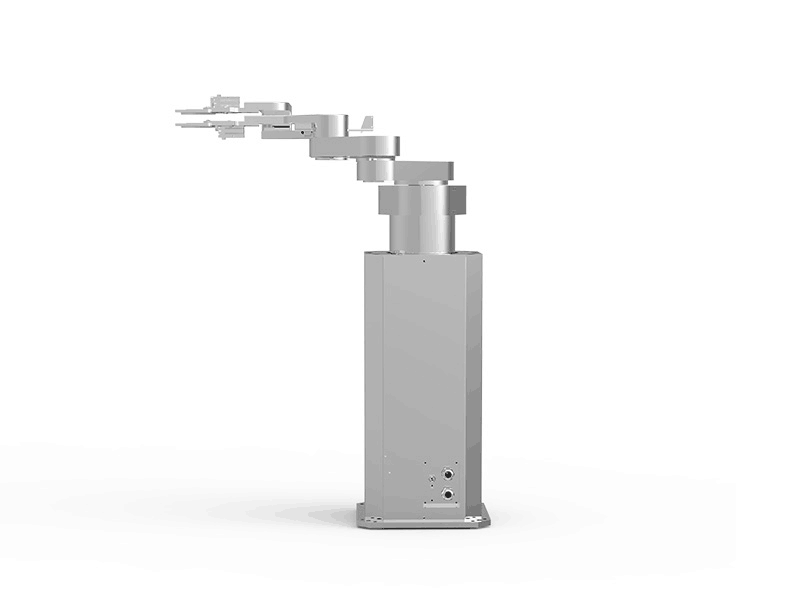

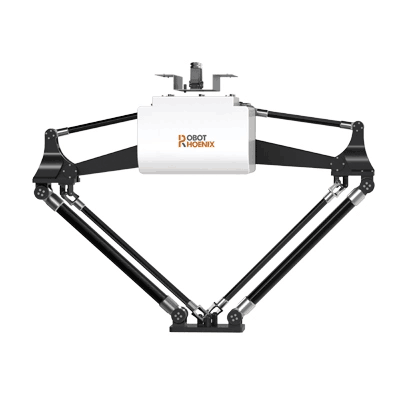

Python-series SCARA robot has a maximum workspace diameter of 1600mm and a maximum load of 10kg.

Scara Robot Working Principle

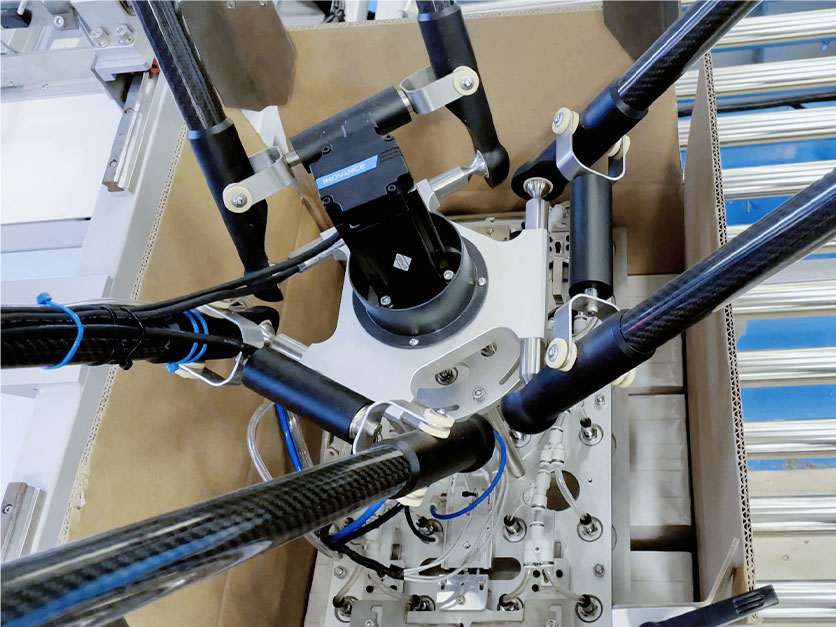

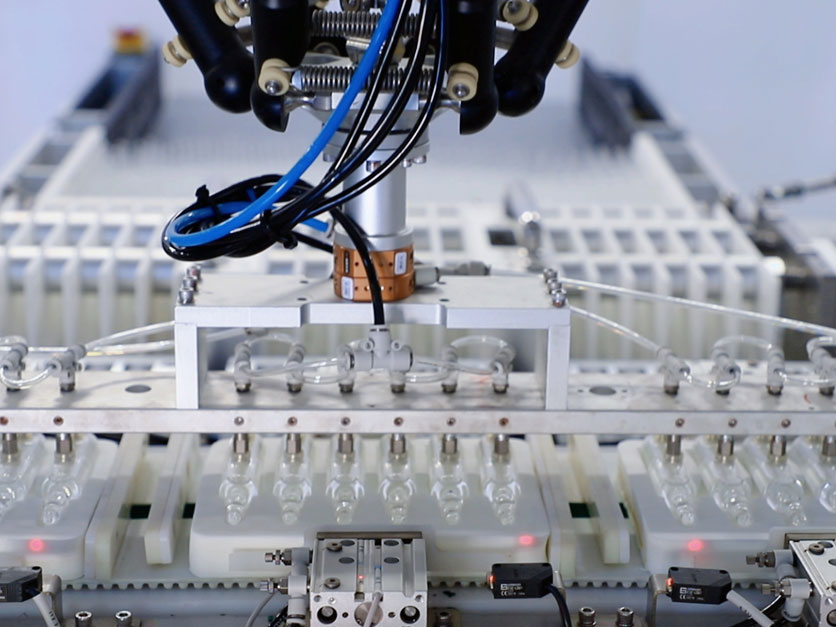

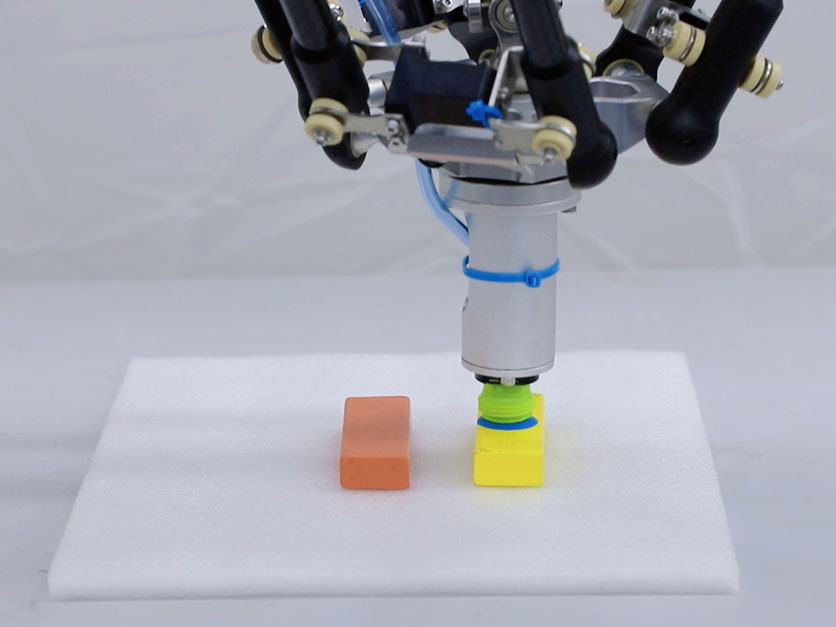

SCARA robot's system is actually a typical system of mechatronics. This collaborative SCARA robot's working principle is that the control system issues action instructions, controls the driver action. The driver drives the mechanical system movement, so that the end operator reaches a certain position in space and realizes a certain gesture, to implement certain tasks. The real-time position of the end operator in space is fed back to the control system by the sensing system, and the control system compares the actual position with the target position, and issues the next action command. It will cycle the instructions until the task is completed.

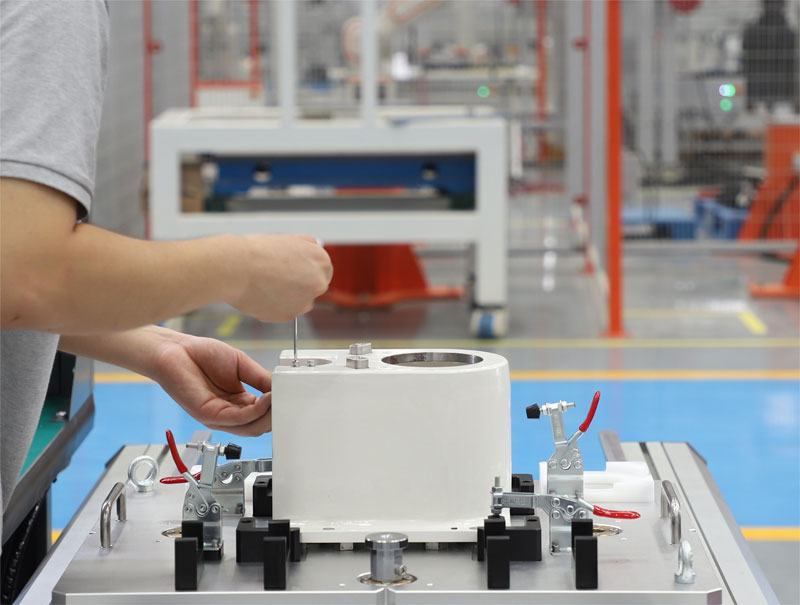

Scara Industrial Robot Design

Produced by Robotphoenix, a leading robot supplier, Python-series SCARA robot's structure adopts modular design to realize a convenient maintenance. Quick gripper changing mechanism makes product line change simply and fast. By a simple and friendly human-machine interaction interface, users can easily and quickly complete machine teaching. In form aspect, the robot adopts lightweight design, and has a small footprint, which can be quickly configured according to the production line changing.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur