1. Development background of industrial robots

Since the word "Robot" was created by Czech playwrights in 1920, robots have developed for nearly a hundred years now. From the original industrial robots used for carrying only, to the second generation of industrial robots with visual sensors and information processing technology, to the "intelligent robot" currently being studied, the development and application of industrial robots have changed with each passing day.

2. Application scenarios of industrial robots

In a short period of more than 50 years, robot technology has developed rapidly. In many manufacturing fields, the most widely used industrial robotics industry is the automobile and auto parts manufacturing industry, and is constantly expanding to other fields, such as mechanical processing industry, electrical industry, rubber and plastic industry, food industry, wood and furniture manufacturing industry. In industrial production, welding robots, grinding and polishing robots, welding robots, laser processing robots, spraying robots, handling robots, vacuum robots and other industrial robots have been widely used.

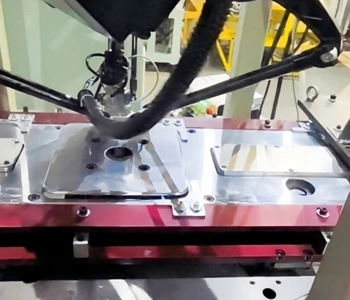

(1) Polishing robot

The grinding and polishing robot is mainly used in aviation, navigation and nuclear power blade grinding and polishing. The robot abrasive belt is used to grind and polish the blade surface, and the flexible contact and visual positioning are used to reduce the grinding and polishing defects.

Compared with manual grinding and polishing, it has the characteristics of short processing time, high profile accuracy, small surface roughness and good processing consistency. It can adapt to heavy load and harsh working environment. High accuracy is required.

(2) Welding robot

The arc welding robot is mainly used in the welding production of various automobile parts, mainly including the melting electrode welding operation and the non-melting electrode welding operation.

In this field, international large industrial robot manufacturers mainly provide unit products to complete equipment suppliers. Application features: fast and stable movement is required, and high positioning accuracy is required.

(3) Laser processing robot

Laser processing robot is to apply robot technology to laser processing, and realize more flexible laser processing through high-precision industrial robots.

(4) Vacuum robot

Vacuum robot is a kind of robot working in vacuum environment. It is mainly used in semiconductor industry to realize wafer transmission in vacuum chamber.

The vacuum manipulator is difficult to import, limited, large in use and versatile, which has become a key component that restricts the R&D progress and product competitiveness of semiconductor equipment. High accuracy requirements.

(5) Spraying robot

The painting robot of Robotphoenix is generally driven by hydraulic pressure and has the characteristics of fast action and good explosion-proof performance. It can be taught by hand handle or point position indication.

Painting robots are widely used in the process production departments such as automobiles, instruments, electrical appliances, enamel, etc. The spraying robot works in a harsh environment, and its accuracy requirements are low.

(6) Handling robot

The handling robot is controlled by computer and has the functions of movement, automatic navigation, multi-sensor control, network interaction, etc. The handling robot can be widely used in flexible handling, transmission and other functions in various industries, as well as in automated warehouse, flexible processing system and flexible assembly system;

At the same time, it can be used as a means of transportation in the sorting of goods at stations, airports and post offices. Its load is large, without strict accuracy requirements.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur