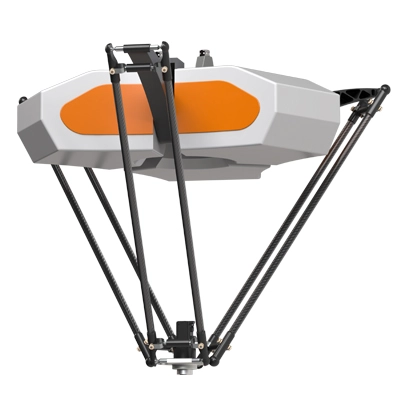

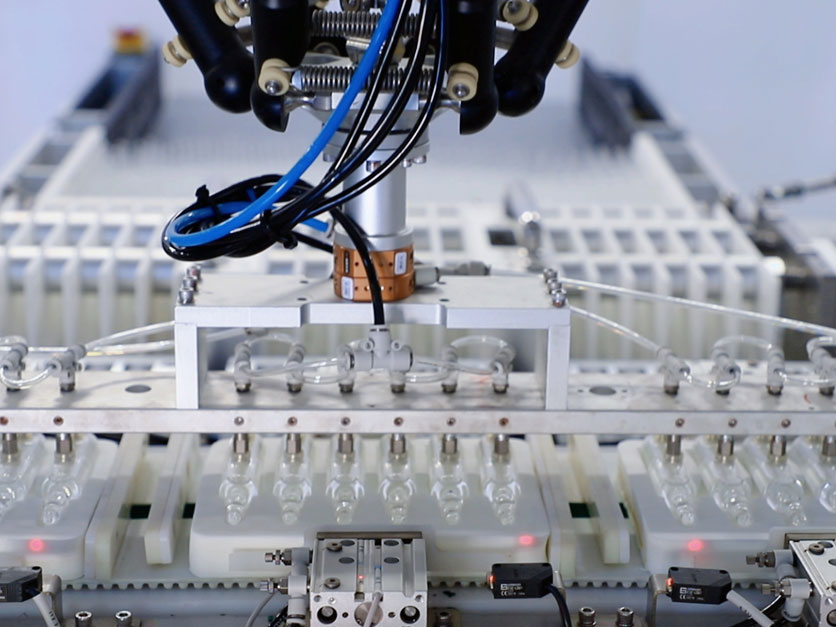

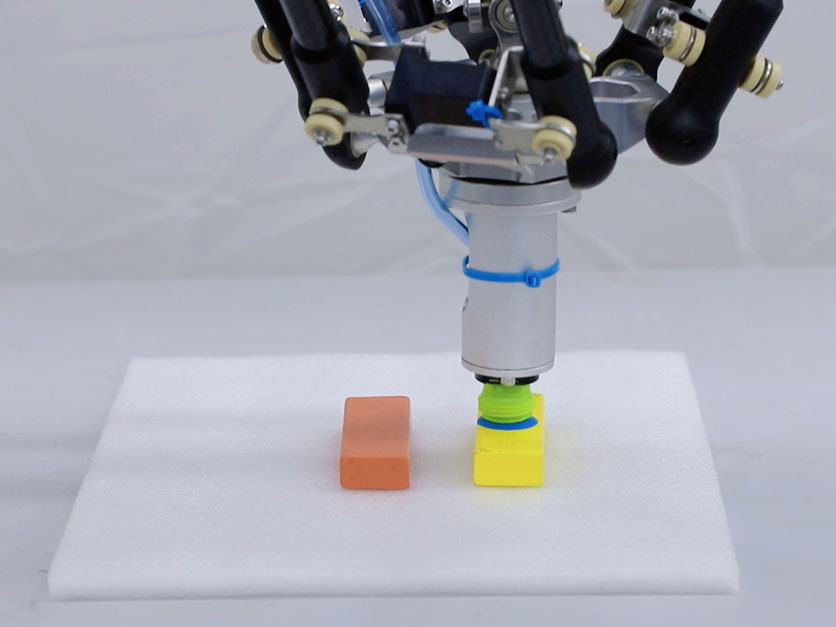

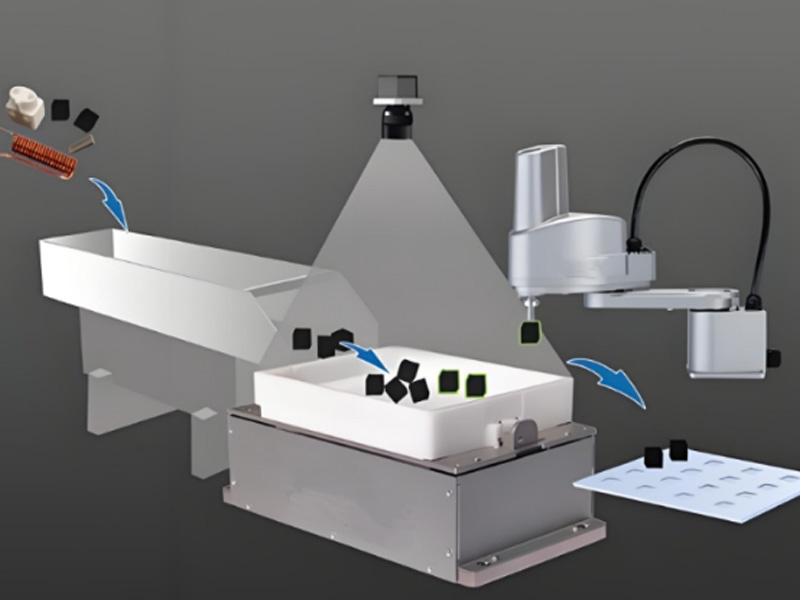

A packaging robot, also known as a pick and place packaging robot, refers to the industrial robot used for packaging in industrial production. These robotic packaging systems, offered by various packaging robot manufacturers, are mainly divided into five categories: bagging, identification and detection, packaging and transportation, packing and filling. The six-axis, SCARA and parallel delta robots self-developed by Robotphoenix, a company owning advanced robotic packaging equipment and one of the premium packaging robot manufacturers, are widely used in the packaging process of various industries, especially in the packaging industry.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur