Traditional vibratory feeders have long served as a classic solution in industrial automation for efficient part feeding. However, they exhibit notable limitations, particularly in precision manufacturing and flexible production environments. Issues such as potential damage to sensitive components, failure to sort irregularly shaped parts, and poor adaptability to flexible production lines have become increasingly prominent.

In industries such as 3C electronics, semiconductors, and medical devices, components are becoming increasingly miniaturized (e.g., thin sheets under 0.2 mm) and surface treatment requirements are more stringent. Traditional vibratory feeders are no longer capable of meeting demands for high precision and non-damaging part handling.

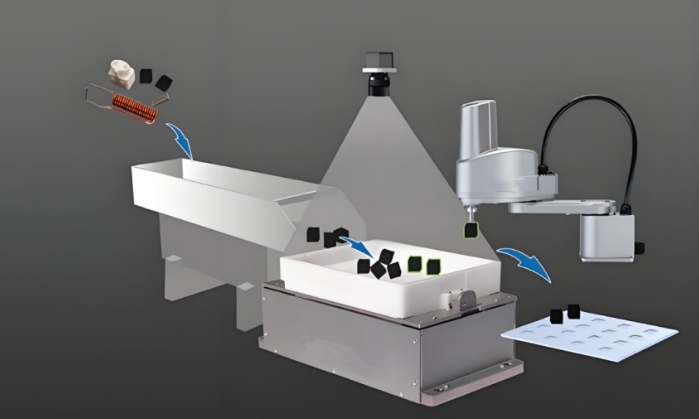

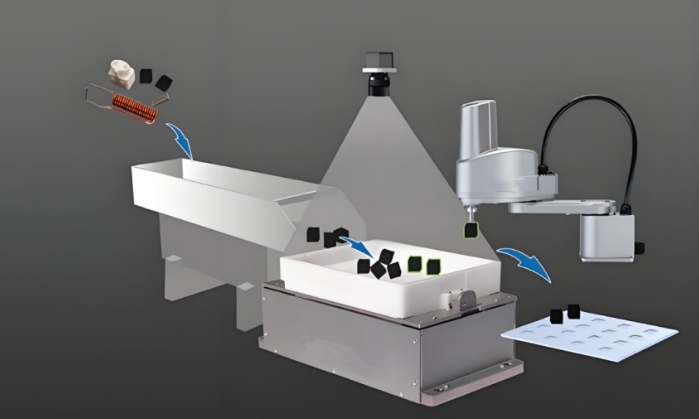

Industrial flexible vibratory feeding solutions (also known as flexible vibratory feeders) integrate voice coil motor drive technology, vision systems, and robotic end-effectors to achieve a comprehensive workflow of part dispersion, visual identification, robotic pick-and-place, and tray arrangement. Thanks to their high adaptability, precision control, and rapid changeover capabilities, these systems are emerging as core equipment in intelligent manufacturing. They are widely applied in 3C electronics, semiconductor manufacturing, automotive parts, medical devices, biomedicine, hardware, and precision manufacturing industries.

Figure 1.1 Schematic Diagram of Flexible Vibratory Feeding

Introduction to YiPack Flexible Vibratory Process Package

2.1 Development Background

To better integrate the complex processes involved in flexible vibratory feeding—such as feeder control, vision systems, and robot coordination—Robotphoenix has developed the YiPack Process Package, tailored for flexible part feeding. The package provides an all-in-one control solution for flexible feeding robots, integrating vision-robot calibration, part picking, refilling, and motion correction into a single production interface. The guided, automated workflow dramatically reduces the technical threshold for operators, allowing even new personnel to quickly become proficient with minimal training.

2.2 Features of YiPack Flexible Vibratory Process Package

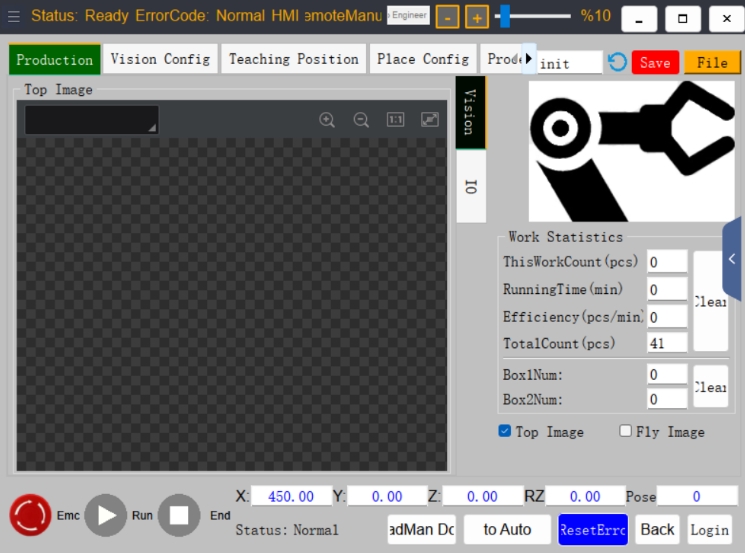

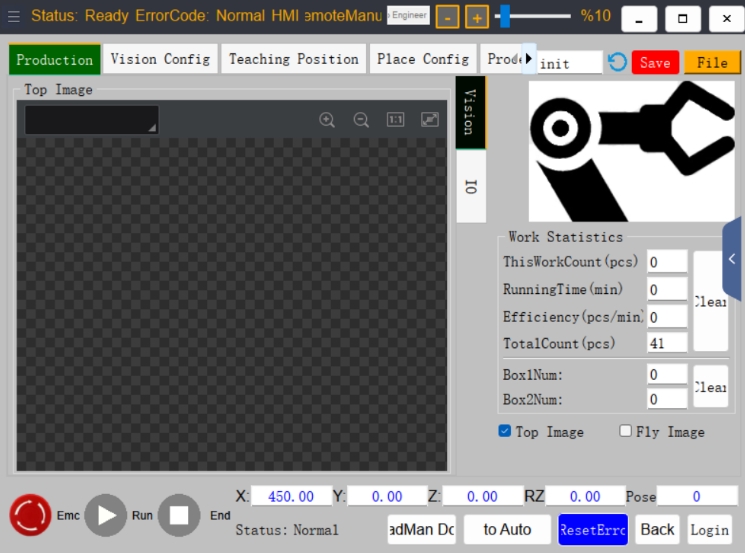

a). Unified Main Interface & Standardized Workflow

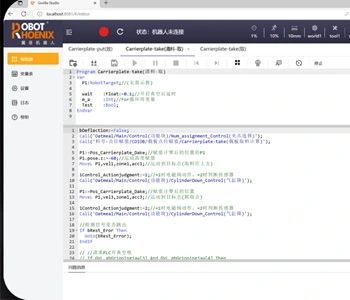

All control over the vibratory feeder, vision system, and robot can be conducted through a single main interface. The main window covers all necessary functionalities for flexible feeding: feeder control, process monitoring, vision settings, teaching points, and tray arrangement. With a no-code operation mode, a clean configuration interface, and step-by-step workflows, the system significantly reduces the technical barrier for operators and simplifies on-site deployment.

Figure 2.1 Main Control Interface

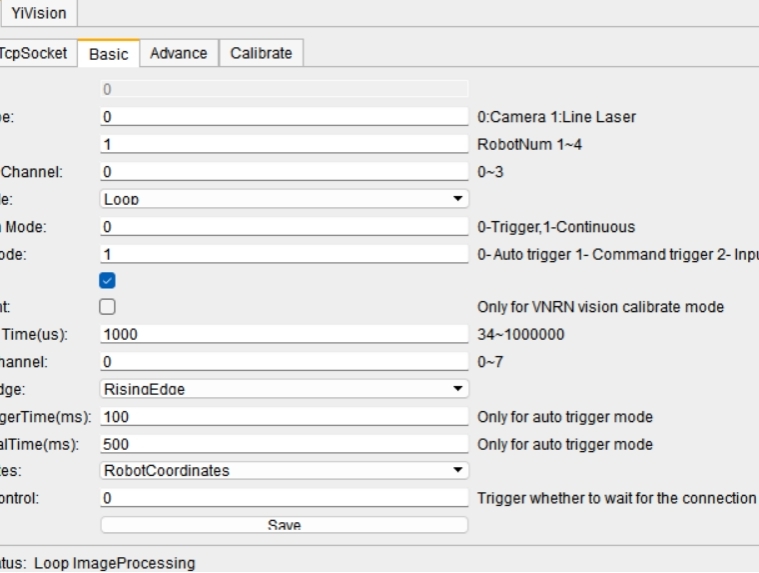

b). Flexible Vision Solutions Paired with Accurate Algorithms

Dual Vision Options: YiPack offers both internal and external vision system options.

The internal vision system, developed in-house, automatically triggers camera capture and processes images without the need for third-party vision software. Recognized objects are directly added to the robot’s object list, enabling rapid integration of vision and robotics.

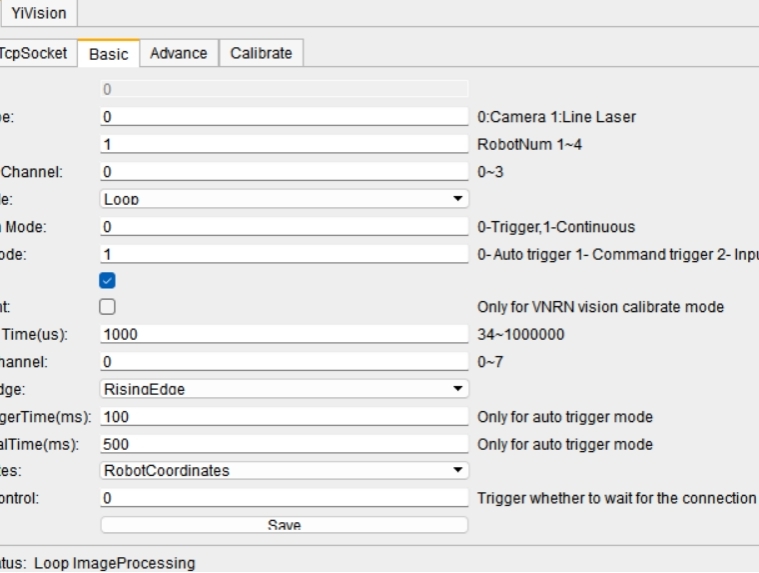

Figure 2.2 Basic Configuration of Internal Vision System

The external vision system supports third-party software (such as VisionPower and Vision Master) for image processing and recognition. Communication with the platform is achieved via socket.

Figure 2.3 Basic Configuration of External Vision System

Vision task setup can be completed in just three steps using a one-click template matching function, allowing operators with no prior vision experience to deploy the system within 30 minutes.

YiPack leverages precise vision algorithms and cutting-edge "on-the-fly" imaging technology to perform real-time localization and correction during high-speed movement. It supports user-defined object templates, facilitating rapid product changeovers. Both dynamic and static imaging modes are available, with cameras flexibly installed in top or side-view configurations to maximize picking efficiency and accuracy.

c). Practical Grabbing and Placing Instructions Aligned with Production Needs

The KingKong-C1 controller comes preloaded with a variety of grab-and-place instructions (e.g., square tray layout, circular tray layout), satisfying diverse production requirements. These practical, ready-to-use instructions allow users to customize their grabbing logic and tray arrangement plans, enabling smarter and more flexible operations.

Flexible Vibratory Production Solution

Equipped with the YiPack Process Package, the Robotphoenix KingKong-C1 Controller represents the optimal solution for flexible vibratory part feeding. Key advantages include:

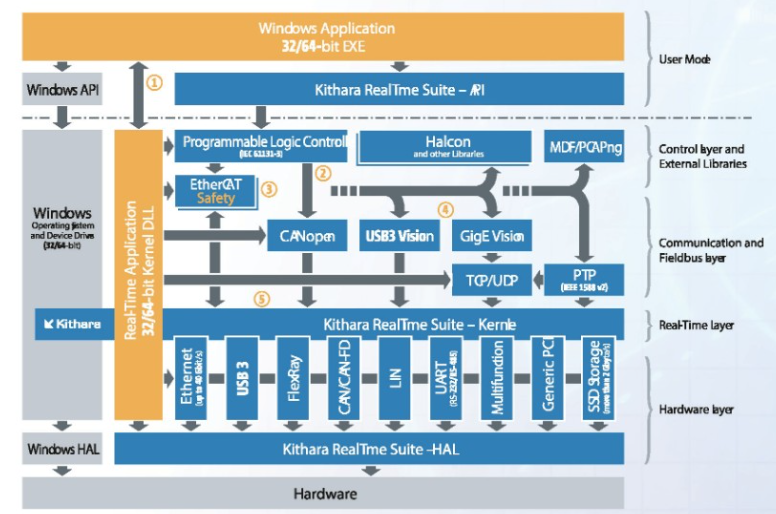

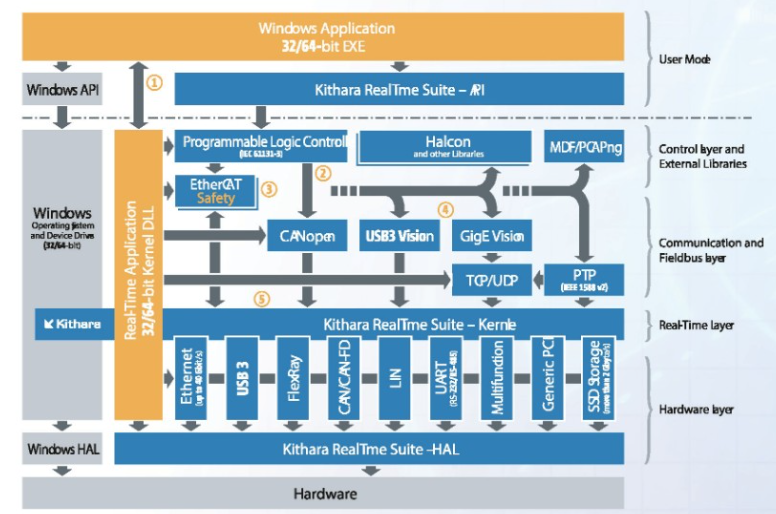

3.1 Hard Real-Time Performance (Microsecond-Level) + Windows Compatibility

Built on the x86 hardware platform, the system adopts multi-core CPU optimization. Real-time and non-real-time tasks are deployed across dedicated cores. Real-time tasks are guaranteed CPU exclusivity, ensuring priority execution and achieving RTOS-level real-time control, while maintaining compatibility with the Windows ecosystem.

Figure 3.1 Software Architecture

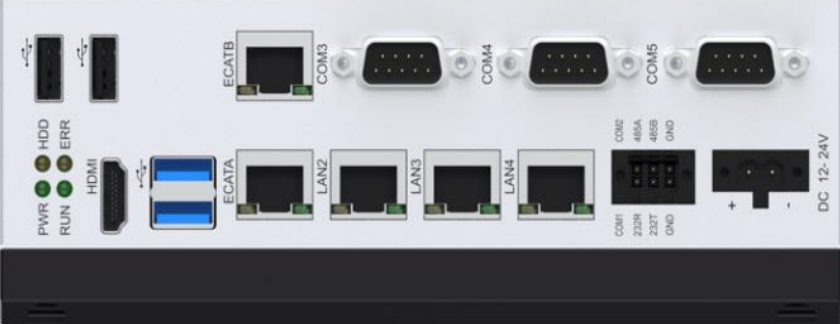

3.2 Strong Hardware Compatibility and Flexible Servo Integration

The KingKong-C1 controller employs EtherCAT communication protocol and supports a variety of servo brands, offering standardized interface protocols across robots, vision systems, and vibratory modules. This eliminates compatibility concerns and enables plug-and-play configuration. Its built-in motion control algorithm ensures millimeter-level precision control of robotic arms.

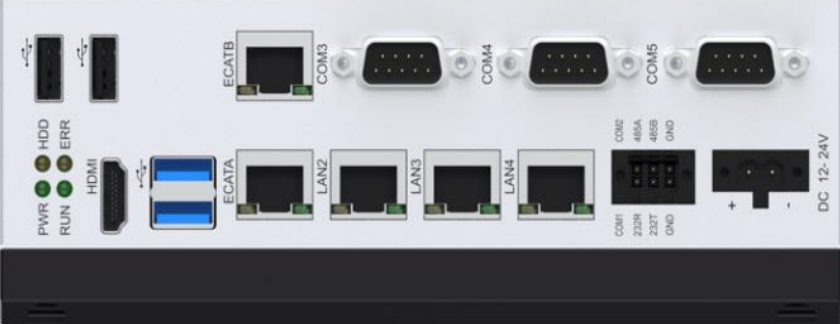

Figure 3.2 Interface configuration of KingKong Controller

3.3 Extensive Experience in Flexible Feeding Station Deployment

Combining the integrated flexible feeding capabilities of the YiPack package with the precise motion control of the KingKong-C1 controller, Robotphoenix has delivered complete feeding solutions—including vibration, recognition, picking, and tray arrangement—for multiple flexible feeding station integrators. Applications span mechanical components, semiconductor parts, medical devices, and more.

Below are several examples of flexible vibratory feeding solutions provided to our customers:

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur