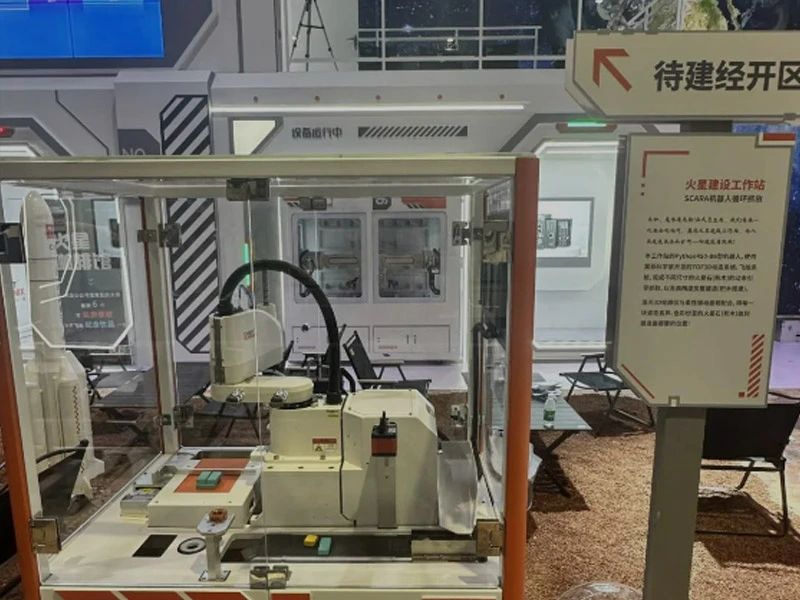

Industrial robots have become an essential part of modern manufacturing processes. These programmable machines can carry out complex tasks with precision and efficiency, making them ideal for repetitive and hazardous jobs, such as assembly, welding, and inspection. However, the capabilities of industrial robots depend on their software applications, which determine their behavior, communication, and feedback. In this blog, we will explore the role of software applications in optimizing the performance and functionality of industrial robots.

Software Architecture and Integration

Industrial robots are composed of hardware and software components that work together to execute tasks. The software architecture of industrial robot software plays a critical role in defining its capabilities and limitations. The software applications must be tailored to the specific needs of the robot, such as the type of movement, workspace, and sensors. Moreover, the software must be integrated with the control system, sensors, and other devices to communicate and coordinate with the environment and other machines. Therefore, the development of industrial robot software requires a multidisciplinary approach that involves mechanical, electrical, and software engineering.

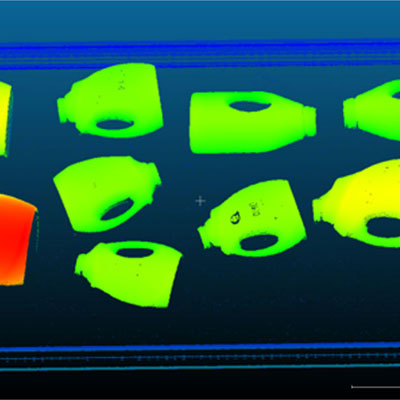

Programming and Simulation

Industrial robot software is programmed to perform various tasks, such as picking, placing, moving, and manipulating objects. The programming language used for industrial robots is usually based on a high-level language that enables the programmer to specify the actions and conditions of the robot in a structured and understandable way. The programming can be done in various ways, including offline programming, online programming, and teach-pendant programming. In addition, simulation software can be used to predict and visualize the behavior of the robot before implementing the program in reality. This approach reduces errors, increases efficiency, and saves time and cost.

Optimization and Maintenance

The software applications of industrial robots can be optimized to improve their performance and functionality. This optimization can be achieved by fine-tuning the programming, adjusting the parameters, and integrating new features and technologies. For instance, the software can be optimized to reduce the cycle time, increase the accuracy, or optimize the energy consumption. Moreover, the software can be updated and maintained to ensure compatibility, security, and reliability. Such maintenance activities include debugging, testing, documentation, and backup. Therefore, the optimization and maintenance of industrial robot software are crucial for achieving the desired productivity and quality.

In conclusion, industrial robot software is a fundamental component of modern manufacturing processes that determines the performance and functionality of robots. The software architecture, programming, simulation, optimization, and maintenance are critical aspects of industrial robot software that require specialized skills and knowledge. As the demand for industrial robots increases, the role of software applications in enhancing the performance and functionality of robots will become more significant. Therefore, the development of industrial robot software should prioritize innovation, quality, and efficiency to meet the needs of the industry and customers.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur