Warehouse Robotics Market Introduction

The ever-evolving world of technology continues to reshape industries across the globe, and warehousing is no exception. The rise of warehouse robotics has transformed the traditional landscape of material handling and automated operations, leading to increased efficiency, reduced costs, and enhanced safety. In this blog, we will delve into the burgeoning warehouse robotics industry from three key aspects: the market overview, prominent warehouse robot manufacturer, and the impact of robotics on warehouse material handling and automation systems.

Warehouse Robotics Industry Overview

The warehouse robotics industry has experienced remarkable growth over the past decade, becoming an essential part of modern supply chain management. The combination of robotics and automation technologies has enabled warehouses to meet the challenges posed by the increasing demand for quick order fulfillment and greater operational efficiency.

The warehouse robotics market has been witnessing a steady surge due to several factors:

Rising E-commerce Sector: The unprecedented growth of the e-commerce industry has necessitated highly efficient and flexible order processing and fulfillment, driving the adoption of robotics in warehouses.

Labor Shortages and Cost Pressures: Many countries are facing labor shortages, and labor costs continue to rise, making it economically viable for warehouse owners to invest in robotic automation.

Advancements in Robotics Technology: With continuous advancements in artificial intelligence, machine learning, and sensor technologies, robots have become smarter, more versatile, and safer, leading to increased adoption.

Focus on Workplace Safety: Warehouse robots offer a safer alternative to human labor in hazardous environments, reducing the number of workplace accidents.

As per recent reports, the global warehouse robotics market is projected to register substantial growth, with a compound annual growth rate (CAGR) of over 10% during the forecast period.

Prominent Warehouse Robot Manufacturer

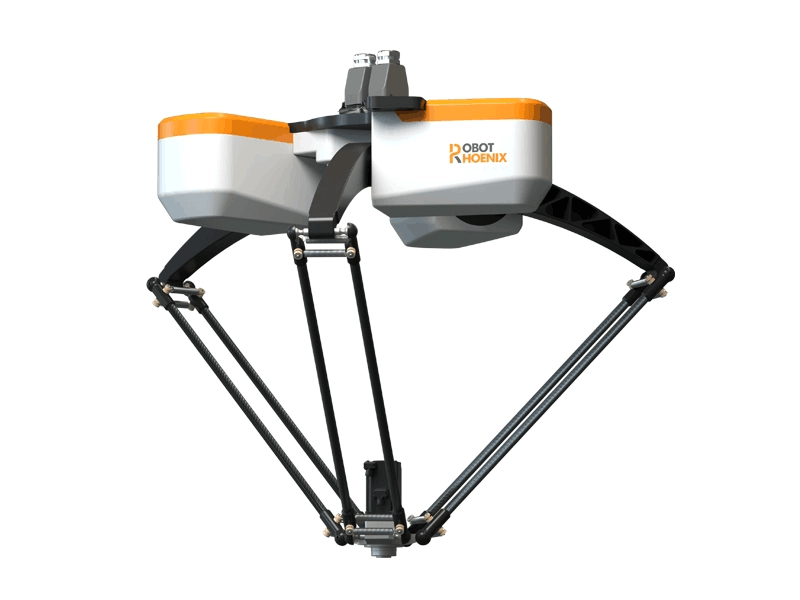

Introduction to Rprobotphoenix: Your Gateway to Cutting-Edge Warehouse Robotics

In the ever-changing landscape of modern warehousing and supply chain management, Rprobotphoenix stands at the forefront as a pioneering of warehouse robot manufacturers. With a commitment to revolutionizing material handling and automation systems, Rprobotphoenix brings innovative and cutting-edge robotic warehouse solutions to streamline warehouse operations and enhance efficiency.

As the demand for swift and accurate order fulfillment grows, Rprobotphoenix's state-of-the-art robotic technologies offer a seamless integration of robotics into warehouse environments. With a focus on safety, scalability, and adaptability, our robotic solutions cater to the diverse needs of warehouses, optimizing processes, and delivering tangible results.

Join us on a journey to explore the world of Rprobotphoenix, where robotics meets warehousing excellence, transforming the way we envision the future of material handling and warehouse automation.

Robotics in Warehouse Material Handling and Automation Systems

The implementation of robotics in warehouse material handling and automation systems has brought about a paradigm shift in the way warehouses function. Here are some of the significant impacts:

Efficient Order Fulfillment: Warehouse automation robotics, such as AMRs and robotic arms, have significantly reduced order processing times. They can swiftly navigate the warehouse, pick items accurately, and pack them efficiently, leading to faster order fulfillment.

Optimized Space Utilization: Robotic warehouse automation system, including AS/RS, make the most of vertical space, enabling high-density storage and better space utilization.

Real-time Inventory Management: With the integration of robotics and automation, warehouses can implement real-time inventory tracking. Robots equipped with RFID technology or barcode scanners can constantly monitor stock levels, minimizing the chances of stockouts and overstock situations.

Enhanced Workplace Safety: By automating hazardous or repetitive tasks, warehouses can create a safer work environment for their employees. Robots are designed to work in proximity to humans without endangering their well-being.

Scalability and Flexibility: Warehouse robots are highly scalable and adaptable to changing business needs. As the volume of orders fluctuates, the number of robots can be easily adjusted, allowing warehouses to meet customer demands efficiently.

Data-Driven Decision Making: Robotics in warehouses generates vast amounts of data related to operations and performance. By leveraging data analytics, warehouse managers can make informed decisions to optimize processes and reduce inefficiencies.

The warehouse robotics market is witnessing unprecedented growth, and its impact on warehouse material handling and automation systems is undeniable. As e-commerce continues to expand and supply chain demands intensify, warehouse owners and managers are recognizing the immense benefits of adopting robotic automation. With a plethora of innovative solutions provided by key warehouse robot manufacturers, the future of warehousing seems brighter than ever. As the technology continues to evolve, we can expect even more sophisticated and efficient warehouse robotics systems, further transforming the logistics industry for the better.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur