Robots in the food industry deliver high precision, speed, and consistent quality across production lines. By automating repetitive, labor-intensive tasks, they help manufacturers ensure product uniformity, reduce raw material waste, and cut labor costs.

From primary processing to final packaging, our Delta and SCARA robots guarantee safe, hygienic, and efficient handling of food products — fully aligned with the industry’s quality standards. As a specialized industrial robot company, Robotphoenix provides robotic solutions that maximize performance, flexibility, and reliability.

Functions and Features of Food Packaging Robots

Our food packaging solutions are powered by high-performance Delta and SCARA robots, designed for speed, precision, and adaptability in modern production lines.

Core Functions

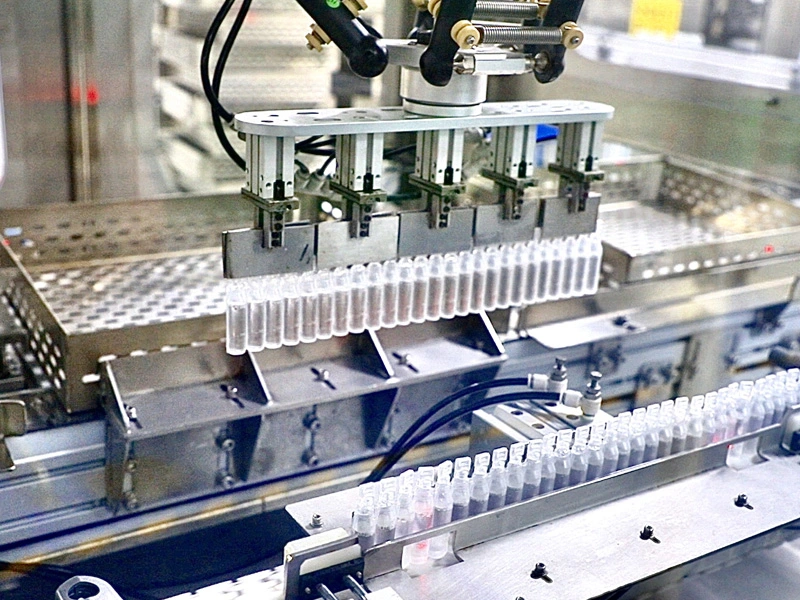

Pick & Place – High-speed transfer of bakery items, candies, snacks, and more from conveyors into trays, boxes, or flow-wrappers.

Sorting & Orientation – Organize products by size, shape, or position — ideal for irregular or randomly positioned items.

Carton & Case Packing – Efficiently load grouped or individual products into cartons, cases, or trays.

Product Arranging – Align and organize products before packaging, streamlining downstream processes like wrapping or case packing.

Vision-Guided Handling – Integrated vision detects position, orientation, and defects in real time, enabling accurate and reliable quality control.

Applications in the Food Industry

Delta and SCARA robots are widely deployed across the food sector, including:

Primary & secondary packaging lines

High-speed flow-wrap infeeds

Sorting and tray/top loading

Confectionery – chocolates, candies, bars

Bakery – cookies, biscuits, pastries

Snack packs & sachets – chips bags, granola bars, seasoning sachets

Dairy products – yogurt cups, cheese sticks

Equipped with the right end effector — such as food-grade vacuum cups or soft grippers — our robots handle even the most delicate products gently yet efficiently, without sacrificing throughput.

Types of Robots Used in the Food Industry

The food industry utilizes various types of robots to improve efficiency, safety, and consistency in food processing and production. Some common types of robots used in the food industry include:

Articulated Robots: The articulated industrial robot is a versatile robotic arm with multiple joints, allowing it to reach various points within its workspace. Articulated robots are used for tasks like picking and placing items, packaging, and assembly in food production lines.

SCARA Robots: Selective Compliance Assembly Robot Arm (SCARA) robots are ideal for high-speed and precise operations like food sorting, handling, and packaging. The collaborative SCARA robot is known for its horizontal reach and speed.

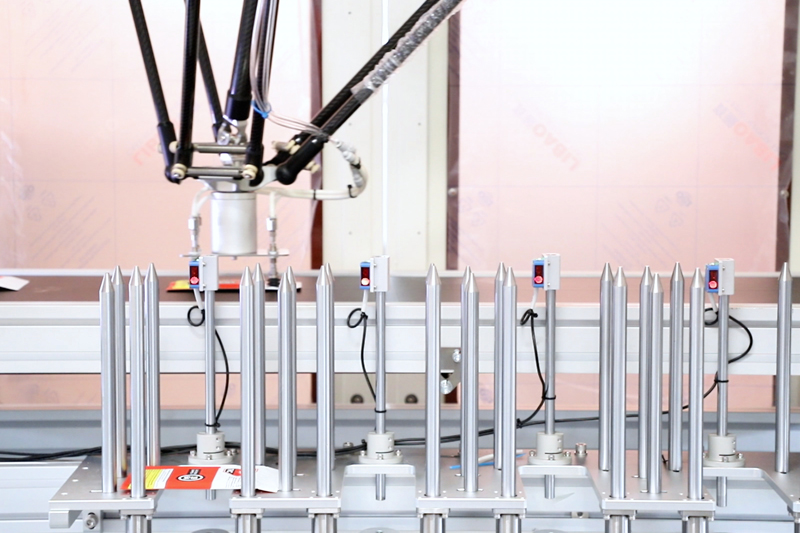

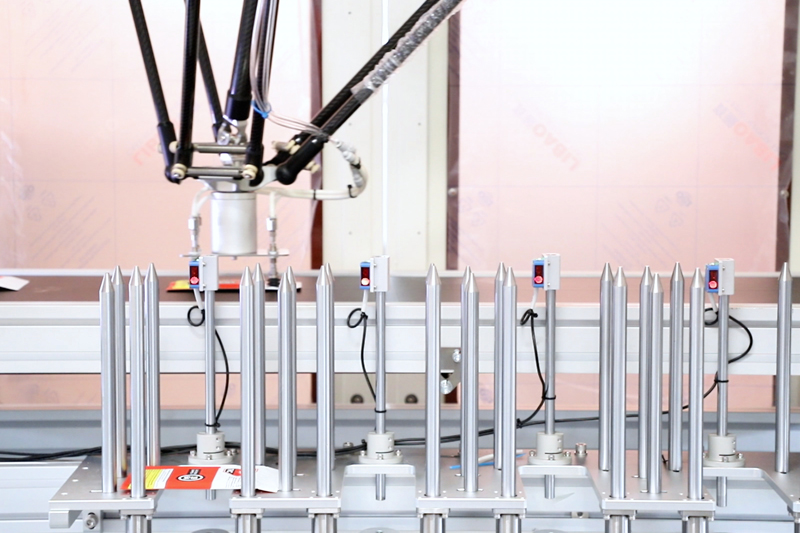

Delta Robots: Also called parallel robots, the delta picker is designed for high-speed pick-and-place operations. They are commonly used in food packaging lines for tasks like placing items into trays or cartons.

Collaborative Robots (Cobots): These industrial collaborative robots are designed to work safely alongside humans. In the food industry, cobots can assist with tasks such as quality control, packaging, and handling delicate food items.

Cartesian/Gantry Robots: These robots use linear motion along three axes (X, Y, Z) and are suitable for applications like loading and unloading trays, boxes, or pallets in food processing.

Sorting and Grading Robots: Specialized robots are used for sorting fruits, vegetables, or other food items based on size, color, or quality criteria. These robots ensure uniformity and consistency in food processing.

These robots play a significant role in enhancing efficiency, maintaining hygiene standards, reducing labor costs, and ensuring food safety in various aspects of food production, processing, and packaging. Each type of robot is chosen based on specific requirements and the nature of tasks involved in food processing operations. As a reliable robot OEM partner, we provide innovative and trustworthy automation solutions tailored to your needs.

Benefits Of Robotics In The Food And Beverage Industry

Improved efficiency: Robotics in the food industry can work continuously without fatigue, increasing production speed and output.

Enhanced food safety: Food manufacturing robots reduce the risk of contamination from human handling and minimize the potential for foodborne illnesses.

Consistency and quality: Robots can follow precise recipes and processes, leading to consistent and high-quality food products.

Labor savings: Food packing robots can perform repetitive tasks that would otherwise require a significant workforce, reducing labor costs.

Flexibility and adaptability: Many food manufacturing robots can be reprogrammed or configured for different tasks, making them versatile in a dynamic production environment.

Gallery Of Robotics In The Food Industry

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur

(1).png)