In modern industrial automation, robotics technology is evolving rapidly from traditional “heavy and repetitive” tasks toward “flexible and efficient” solutions. Especially in fast sorting and precise picking processes, Delta Robots are widely adopted for their high speed and precision. As a professional provider of Delta Robot automation solutions, Robotphoenix focuses deeply on both static picking and dynamic tracking picking technologies, helping customers in precision manufacturing and food packaging improve efficiency and yield. This analyzes the differences between static and dynamic tracking picking with Delta Robots and showcases Robotphoenix’s technical strengths.

1. Static Picking: Stable, Efficient, and Mature

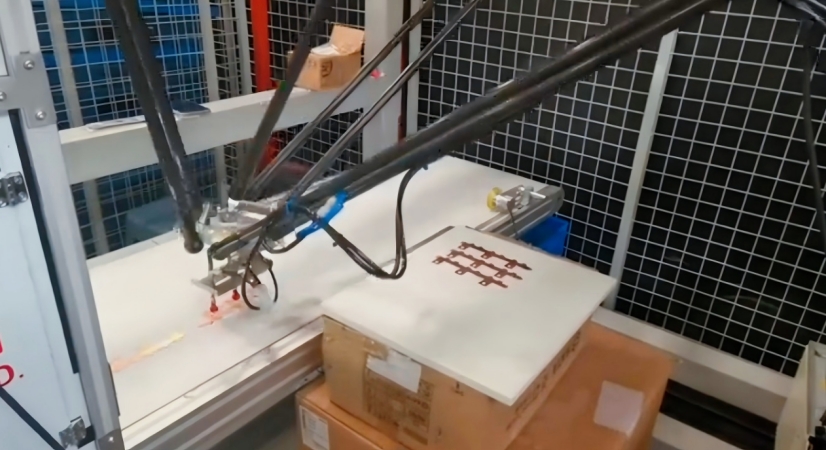

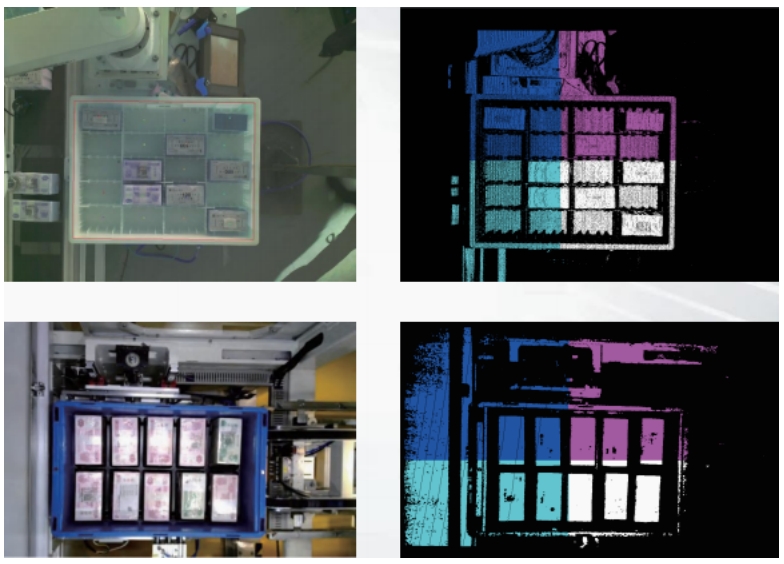

Static picking is the most common and mature form of Delta Robot application. Its basic principle is: when the target material is stationary, the vision system first captures images and calculates coordinates, after which the robot executes the picking operation.

Features and Advantages:

High Stability: Since the object is stationary, image acquisition quality is higher, coordinate recognition is more accurate, and the system runs reliably.

Simple System Configuration: A fixed vision system and picking program in a designated photo area can handle most application needs.

Wide Application Range: Including but not limited to plastic products, electronic components, disposable tableware, and irregular metal parts.

Low Cycle Time Requirements: Suitable for medium-speed lines or manual loading/unloading operations with lower cycle demands. Easy deployment and lower costs.

2. Dynamic Tracking Picking: Higher Challenge, True Capability

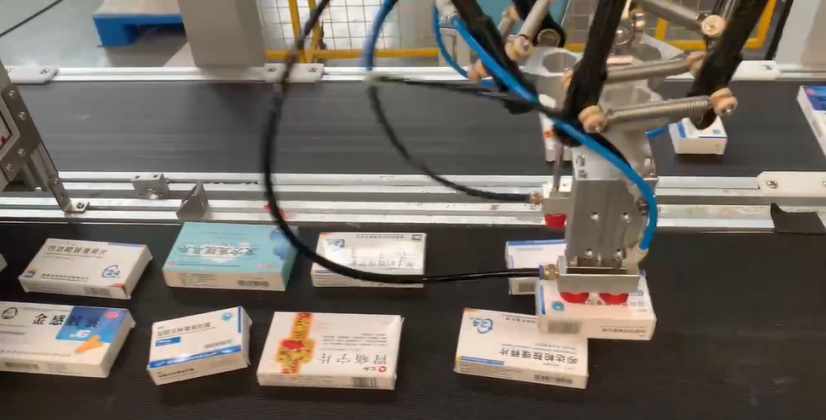

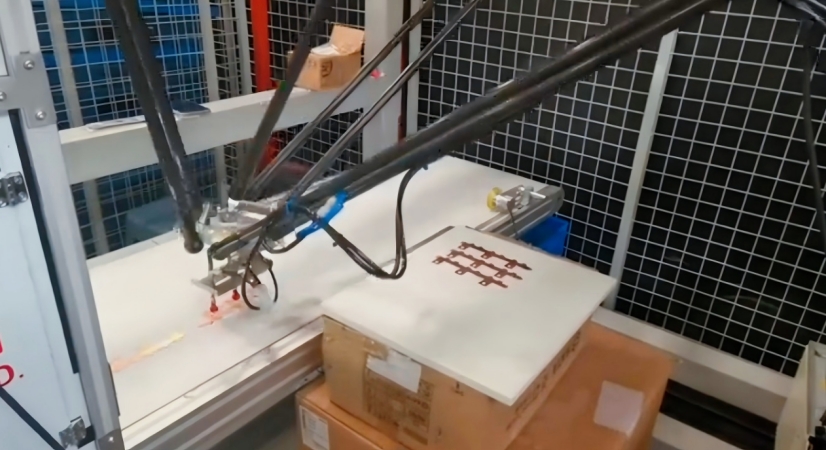

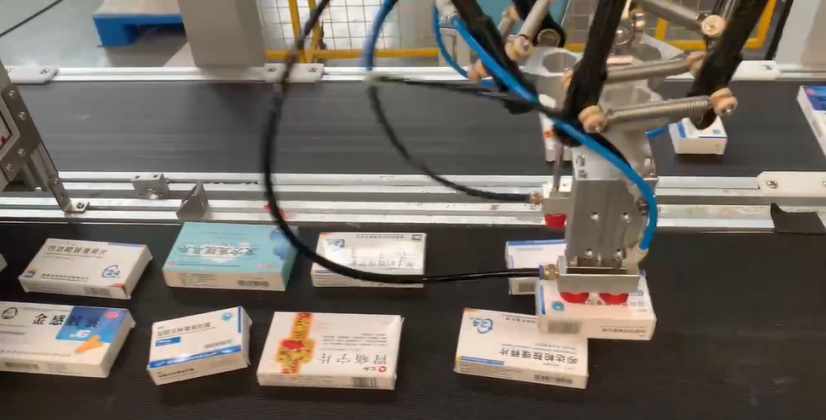

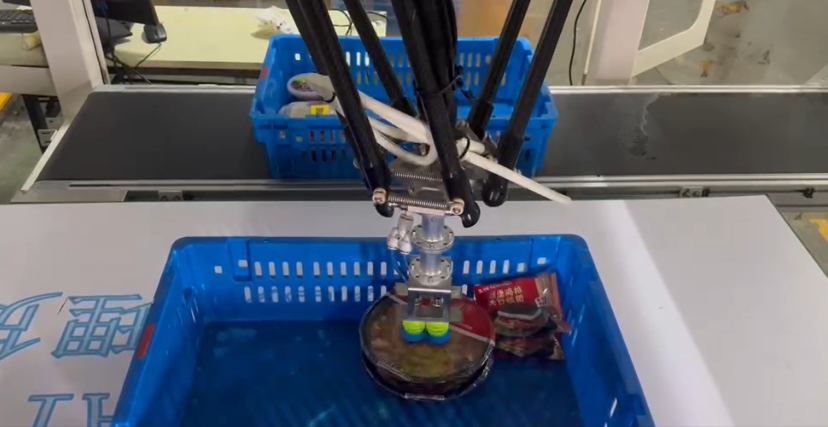

Unlike static picking, dynamic tracking picking (also known as picking in motion or dynamic positioning) requires the robot to complete visual recognition while the object is in continuous motion, and then convert visual coordinates into actual object positions to perform fast picking.

Principle Explanation:

Materials continuously move along a conveyor or chute. The vision system uses a trigger to capture images as the object passes through the camera field and predicts its future position using belt speed compensation.

The control system converts each recognized pose into robot coordinates using motion compensation algorithms.

The Delta Robot plans its trajectory in advance based on the predicted coordinates and performs synchronized picking at the estimated position of the moving object.

Technical Challenges:

High Real-Time Requirements: Demands fast visual recognition and data processing.

Strong Synchronization: The robot must be perfectly synchronized with the conveyor to avoid picking errors.

High Precision Requirements: Especially in scenarios where the object is small, complex in shape, or has tight placement tolerances.

Therefore, dynamic tracking is typically used in high-speed automation lines with continuous product flow, where manual handling is impractical. It is often still in testing or partial application stages due to its high technical barriers.

3. Robotphoenix’s Strengths and Practical Experience

As a manufacturer and integrator specializing in high-speed picking and precision positioning, Robotphoenix has accumulated extensive experience in both static and dynamic Delta Robot picking applications:

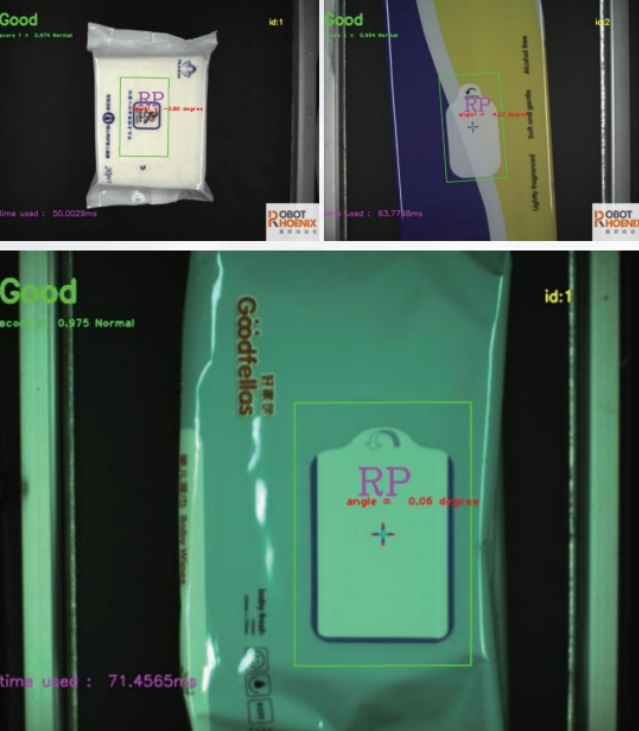

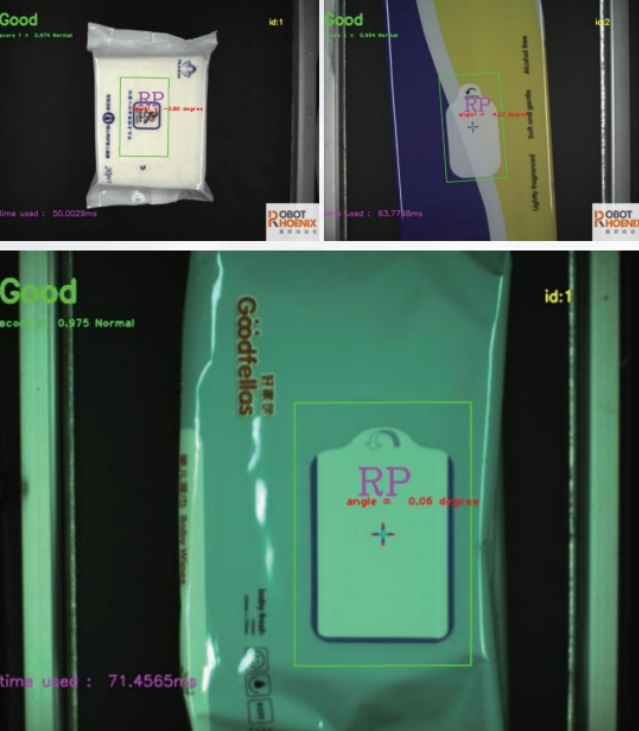

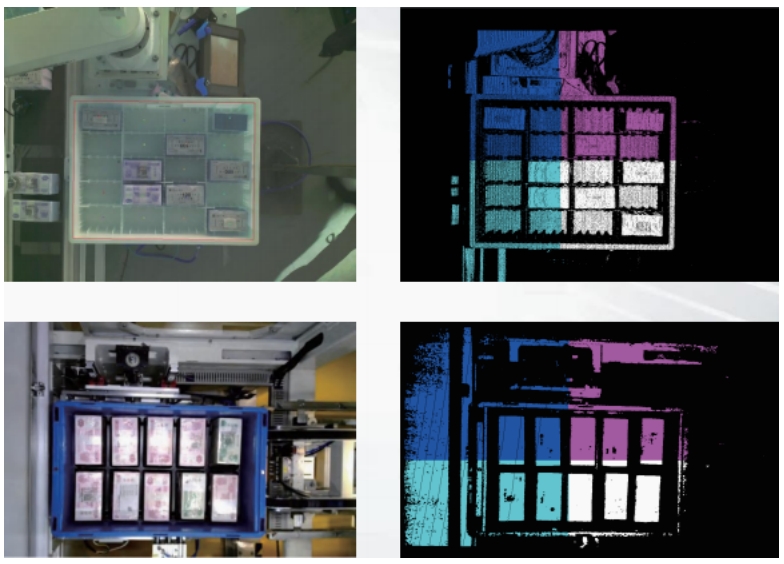

(1). In-House Vision System Integration

We flexibly configure static or dynamic vision systems according to customer site conditions to ensure recognition efficiency and system stability.

(2). Professional and Reliable Control Strategies

Robotphoenix has developed proprietary Delta Robot control logic, featuring high-precision trajectory compensation, coordinate conversion, and optimized picking algorithms. We support mainstream industrial communication protocols such as Profinet and EtherCAT.

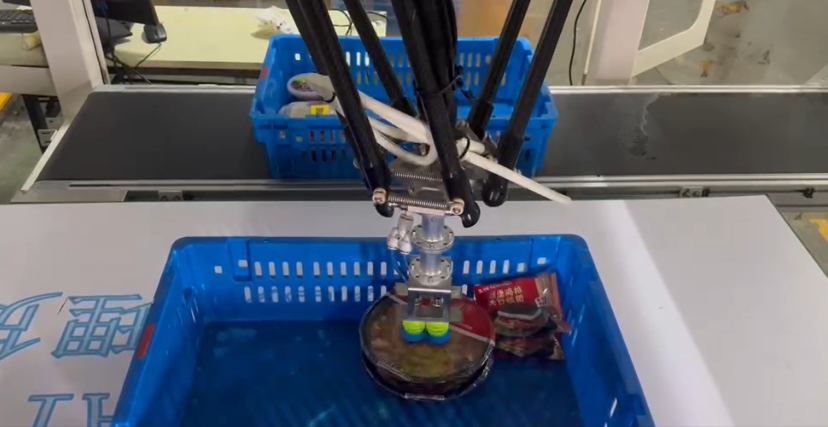

(3). Comprehensive Testing Platforms

We have built several demo testing platforms internally to simulate continuous conveyor operation. We conduct dynamic tracking picking testings on materials of various cycle times, sizes, and shapes to solve potential issues before full-scale production.

4. Application Selection Guidelines

Selection Scenario | Static Picking | Dynamic Tracking Picking |

Material Status | Stationary | Continuously Moving |

Technical Difficulty | Low | High |

Cycle Time Requirement | Medium to Low Speed | High Frequency and Speed |

Precision Requirement | Moderate | High |

Budget Consideration | Cost-Effective | Relatively Higher |

Application Scenarios | Simple Sorting, Assembly | Continuous Feeding, Fast Lines |

Robotphoenix customizes picking solutions based on the customer’s specific needs, aiming for efficiency, intelligence, and flexibility while maintaining system stability.

5. Conclusion

Static and dynamic picking represent the two core directions of Delta Robot application: “stability” and “speed.” With deep technical expertise in system integration, visual positioning, and trajectory planning, Robotphoenix offers customers complete end-to-end services — from solution design and system testing to after-sales support. Whether your production line requires a cost-effective static picking solution or a flexible and efficient dynamic tracking system, Robotphoenix can deliver a reliable, high-performance, and sustainable automation solution tailored to your needs. Feel free to contact us for more project examples and technical insights.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur