Product assembly is often the most complex stage of manufacturing. It requires not only precision but also the ability to handle repetitive operations at speed. Traditional manual or semi-automatic methods often struggle with labor shortages, inconsistent quality, and limited throughput — creating bottlenecks in the entire production line.

Smarter Way to Assemble

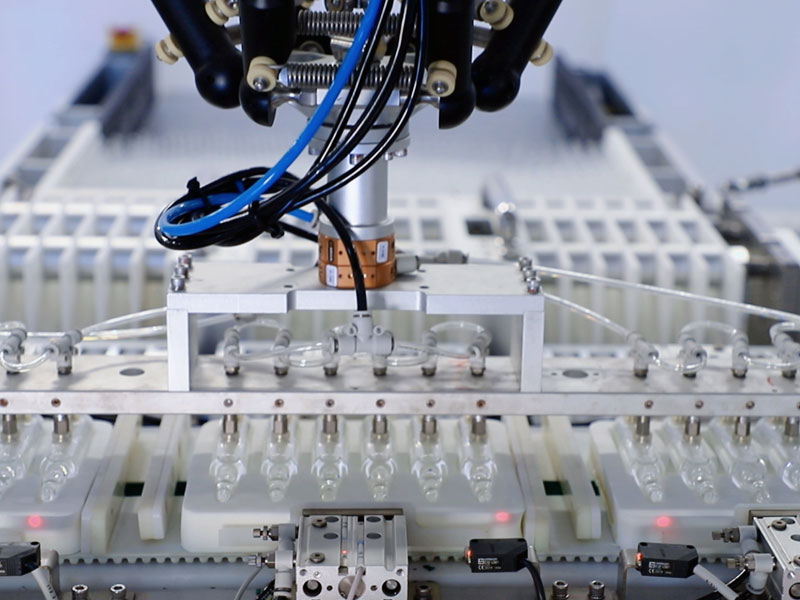

Our robotic assembly solutions use Delta and SCARA robots designed specifically for high-speed, high-precision handling. They can perform a variety of assembly tasks with consistent accuracy. By replacing manual labor in repetitive or ergonomically challenging steps, manufacturers achieve stable quality and faster cycles, while also reducing operator fatigue and error rates.

Meet Dynamic Production Needs

Modern industries demand flexibility. Our assembly line robots can quickly adapt to different product models, assembly requirements, and layout changes — whether in consumer goods, automotive parts, or electronics. This agility makes robotic assembly automation not only suitable for mass production but also for multi-variety, small-batch manufacturing.

The Value to Our Customers

Consistent Quality: Stable and repeatable assembly minimizes defects and rework.

Higher Efficiency: Faster cycle times reduce production bottlenecks.

Lower Costs: Less dependency on manual labor lowers operational expenses.

Scalable Growth: Easy to expand or reconfigure as production needs evolve.

Our Experience

Over the years, we have implemented robotic assembly systems across a wide range of industries, delivering measurable improvements in efficiency and quality. From component fastening in automotive supply chains to part alignment in electronics, our solutions have helped manufacturers modernize their production while remaining competitive.

As one of the experienced industrial robot manufacturers and a dedicated robot OEM partner, we provide automated robotic assembly solutions powered by proven robotics technologies — designed to make manufacturing smarter, more efficient, and future-ready.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur

(1).png)