In the world of industrial automation, articulated robots have emerged as game-changers, revolutionizing the way various industries operate. These versatile machines, also known as articulated industrial robots, offer a wide range of applications and capabilities, making them a crucial part of the modern manufacturing landscape. In this blog, we will delve into the fascinating world of articulated robots, exploring their types, applications, significance, and key players in the market.

The Rise of Articulated Industrial Robots

Articulated industrial robot, also referred to as robotic arms, are a type of robotic system with multiple joints resembling a human arm. These joints provide flexibility and maneuverability, allowing the robot to mimic human-like movements and perform complex tasks. Developed in the mid-20th century, these robots initially found use in controlled environments like automotive assembly lines. However, advancements in technology and cost reductions have led to their widespread adoption across various industries.

Types of Articulated Robots

Six-Axis Articulated Robot:

One of the most common types of articulated robots is the six-axis robot. As a typical type of 6-axis delta robot, these robots consist of six rotating joints, providing them with unmatched dexterity and versatility. The six-axis configuration enables them to perform complex movements and reach almost any point within their workspace, making them ideal for tasks that require a high degree of precision, such as welding, painting, and material handling.

Collaborative SCARA Robots:

SCARA stands for Selective Compliance Assembly Robot Arm. SCARA robots have three or four axes and are designed for tasks that involve fast and precise horizontal movements. Their rigid structure allows them to achieve high speeds, making them suitable for pick-and-place operations and assembly tasks in industries like electronics and consumer goods.

Delta Industrial Robot:

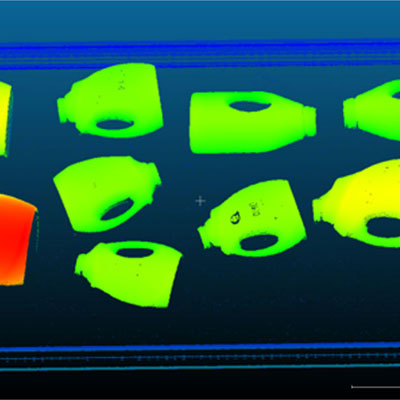

Delta robots are known for their unique design featuring three arms connected to a central base. These robots are used in applications that require high-speed and high-precision tasks, such as packaging, sorting, and food processing. Their ability to rapidly move in all three dimensions makes them efficient for repetitive tasks in the food and beverage, pharmaceutical, and electronics industries.

What Are Articulated Robots Used For?

Articulated robots have found applications across a wide range of industries due to their flexibility and efficiency. Some common uses include:

Robot Application In Manufacturing: In the automotive industry, articulated robots are widely used for assembling components, welding, painting, and quality control. They improve productivity, reduce errors, and ensure consistent quality.

Robotics Pharmaceutical Automation: Articulated robots are used in pharmaceutical applications for tasks such as dispensing, packaging, and quality inspection. Their hygienic design ensures compliance with strict industry standards.

Robotics In Food Industry: In food processing, articulated robots perform tasks like packaging, sorting, and palletizing, ensuring faster production and maintaining high sanitation standards.

Robotics In Renewable Energy: As the capabilities of robotics continue to evolve, the synergy between technology and renewable energy will undoubtedly play a pivotal role in building a cleaner, greener, and more sustainable future for generations to come.

Articulated Robot Manufacturers

The demand for articulated robots has led to a competitive market with several prominent manufacturers and innovators:

a. ABB Robotics: ABB is a global leader in industrial automation and offers a diverse range of articulated robots catering to various industries.

b. Fanuc Corporation: Fanuc is a Japanese company renowned for its robotic solutions, including six-axis articulated robots used in manufacturing and automation processes.

c. Yaskawa Electric Corporation: Yaskawa is a major player in the robotics industry, offering a wide array of articulated robots and solutions for industrial automation.

d. KUKA Robotics: KUKA is a German company known for its advanced robotic systems, including six-axis robots suitable for industries like automotive and aerospace.

e. Universal Robots: Universal Robots specializes in collaborative robots, or cobots, which work alongside human operators in a safe and efficient manner.

Robotphoenix, as a professional articulated robot wholesale supplier, dedicated to the development and production of robotic systems. These systems range from simple machines with basic functions to highly sophisticated robots capable of complex tasks, artificial intelligence, and autonomous decision-making. Leveraging their engineering expertise and research capabilities, robot manufacturers create robots tailored to meet the specific needs and requirements of diverse industries.

The articulated robots market is experiencing exponential growth as industries worldwide recognize the benefits of automation. From manufacturing and assembly to healthcare and beyond, these robots have revolutionized the way we work and produce goods. With ongoing technological advancements, we can expect even more sophisticated and intelligent articulated robots in the future. As the market continues to expand, these versatile machines will undoubtedly shape the future of industrial automation and drive innovation across various sectors.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur