In an era of technological innovation, robotics has emerged as a transformative force across various sectors. Among the remarkable applications, inspection robots have revolutionized the way industries assess and maintain their assets. From hazardous environments to remote and hard-to-reach areas, these intelligent machines are transforming inspections, enhancing safety, and improving operational efficiency. This blog delves into the dynamic world of inspection robots, exploring their applications, market trends, and the future of this burgeoning industry.

The Rise of Inspection Robots

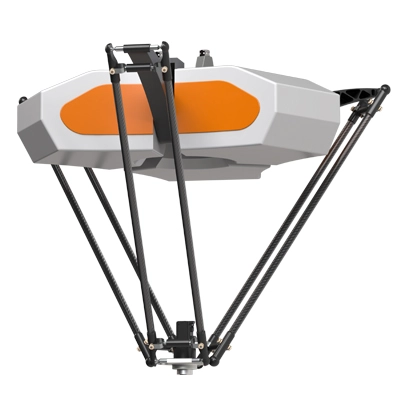

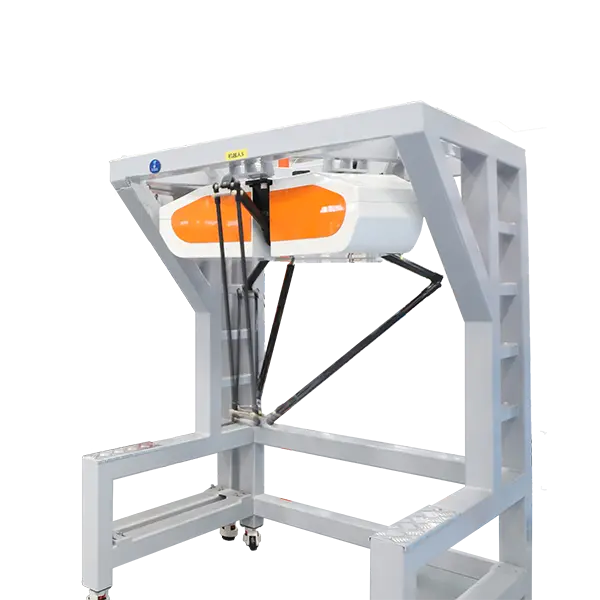

Inspection robots are specialized machines designed to perform visual assessments, collect data, and execute routine inspections, often in places where human access is limited or dangerous. Their versatility and capability to carry various sensors and cameras make them indispensable for industries like oil and gas, energy, construction, infrastructure, and more.

Key Applications of Inspection Robots

Oil and Gas Industry: Inspection robots have significantly transformed the oil and gas sector, where they inspect pipelines, tanks, and other critical infrastructure, reducing the need for costly and hazardous manual inspections.

Energy and Power Plants: These robots are employed to assess the structural integrity of power plants, detect potential faults, and monitor equipment conditions, ensuring smooth operations and minimizing downtime.

Infrastructure and Construction: Industrial inspection robots play a vital role in assessing bridges, tunnels, and high-rise buildings, enabling engineers to identify defects and plan timely maintenance.

Aerospace and Aviation: In aviation, inspection robots are used to examine aircraft surfaces, engines, and components, enhancing safety and reducing maintenance costs.

Nuclear Facilities: Inspection robots are instrumental in inspecting radioactive environments, safeguarding human workers from potential risks.

Market Trends Driving the Growth

Advanced Sensor Integration: Inspection robots in Robot Phoenix are now equipped with cutting-edge sensors, including LiDAR, thermal imaging, and ultrasonic devices, enhancing their ability to capture detailed data and conduct comprehensive assessments.

Autonomous Navigation: The integration of artificial intelligence and machine learning has enabled inspection robots to navigate autonomously, reducing the need for human intervention and improving their adaptability to dynamic environments.

Remote Operation and Connectivity: With the advent of 5G and improved connectivity, operators can remotely control inspection robots, facilitating real-time data transmission and instant decision-making.

Miniaturization and Swarming: The development of miniaturized inspection robots and swarming technology allows multiple robots to collaborate effectively, increasing coverage and efficiency in complex inspection scenarios.

Cloud-Based Data Storage and Analysis: Inspection robots are now equipped to store and analyze vast amounts of inspection data in the cloud, enabling predictive maintenance and data-driven decision-making.

Advantages of Inspection Robots

Enhanced Safety: By replacing human inspectors in hazardous or challenging environments, inspection robots mitigate potential risks and accidents, ensuring the safety of workers.

Cost Efficiency: Inspection robots lead to substantial cost savings by reducing the need for human labor, minimizing downtime, and preventing costly damages through timely detection of issues.

Improved Accuracy and Consistency: Robots deliver consistent and precise data, eliminating human error and subjective judgments, resulting in more reliable inspection outcomes.

Time Savings: Inspection robots can complete tasks at a faster pace than human inspectors, accelerating inspection processes and improving overall efficiency.

Access to Remote Areas: In sectors like offshore energy or rugged terrain, inspection robots enable access to remote and challenging locations, which would otherwise be difficult for human inspection.

Challenges and Future Prospects

Technological Complexity: Developing advanced inspection robots with complex sensors and AI requires substantial expertise, driving up research and development costs.

Regulatory Compliance: Adhering to safety regulations and gaining approval for the use of inspection robots in various industries can present challenges for market penetration.

Data Security and Privacy: With the increased use of cloud-based data storage, ensuring data security and privacy will be critical to gaining stakeholders' trust.

Industry-Specific Adaptation: Different industries have unique inspection requirements, necessitating tailored solutions for specific applications.

The future of the inspection robots market appears promising, with ongoing technological advancements, increased automation, and cost optimization. As industries continue to prioritize safety, efficiency, and data-driven decision-making, inspection robots will undoubtedly play a pivotal role in shaping the way inspections are conducted across diverse sectors. The symbiosis of human expertise and robotic capabilities will pave the way for a safer, more efficient, and smarter industrial landscape.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur