Industrial robots have become the most common tool in the production process from the "luxury" that only large enterprises can use to the promotion and use of many small and medium-sized enterprises. The industrial robot industry has the potential to expand horizontally and promote all industries, so it can be seen that the industrial robot will eventually become the inevitable choice of manufacturing enterprises, and the future development will make the industrial production and even the human society undergo earth-shaking changes.

Characteristics of industrial robots.

1. Programmable

The further development of production automation is flexible automation. The industrial robots can be reprogrammed according to the needs of its working environment, so it can play a good role in the flexible manufacturing process of small batch and multiple varieties with balanced efficiency.

2. Humanization

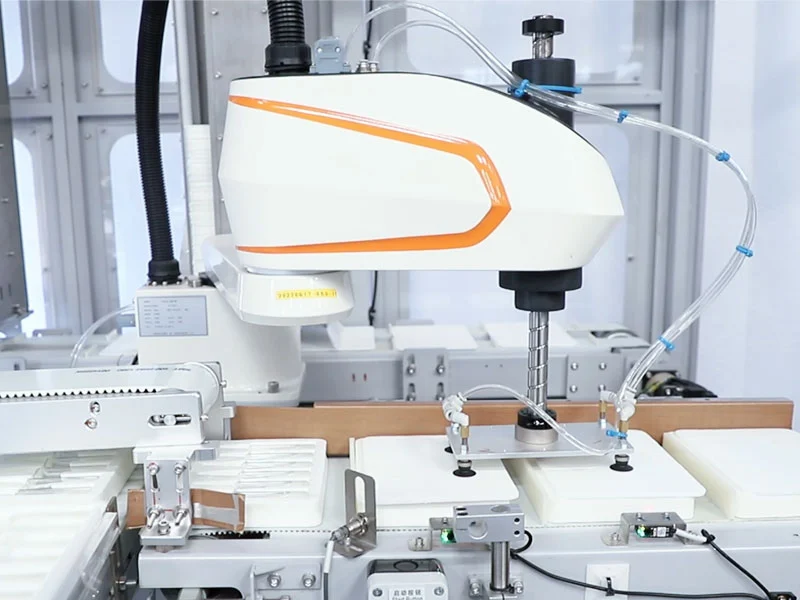

The mechanical structure of industrial robot is similar to that of human walking, waist turning, big arm, small arm, wrist, paw and other parts, and the control is computer. In addition, intelligent industrial robots also have many "biosensors" similar to human beings, such as skin contact sensors, force sensors, load sensors, visual sensors, acoustic sensors, language functions, etc. The sensor improves the adaptive ability of the industrial robot to the surrounding environment.

3. Generality

In addition to specially designed industrial robots, general industrial robots have good versatility when performing different tasks. For example, changing the end manipulator (paw, tool, etc.) of the industrial robot hand can perform different tasks.

Advantages of industrial robots.

1. Cost savings

The robot can operate 24 hours. Effectively save labor costs. In addition, using the mode of industrial manipulator operation, the automatic assembly line can save more space and make the whole plant planning smaller and more compact.

2. High production efficiency

The time consuming for a robot to produce a product is fixed. In the same life cycle, the output of the manipulator is also fixed, and will not fluctuate from high to low. In addition, the production time of each the first mock examination is fixed, and the product yield is also high, so the use of robots for production is more in line with the interests of robotics and automation companies.

3. High safety factor

The use of manipulator production can guarantee the work safety of workers to a greater extent. There will be no industrial accidents caused by work negligence or fatigue. The industrial robot is used for operation, with higher accuracy, stability and safety, which can ensure the safety of personnel.

4. Easy to manage

In the past, it was difficult to accurately guarantee the daily production volume in enterprises, because the attendance and work efficiency of employees were variables, and were easy to be interfered by external factors. However, after the use of robots for production, the number of employees was reduced, and the staff management and production management of enterprises were more efficient.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur