In the intricate web of modern logistics and manufacturing, the efficiency of palletizing operations plays a pivotal role in shaping the overall productivity and cost-effectiveness of supply chain processes. Robotic palletizing automation has emerged as a transformative force, delving into the depths of efficiency with unprecedented precision and speed. This passage navigates the profound realm of robotic palletizing automation, unraveling the layers of technological sophistication that contribute to its exceptional efficiency.

Unraveling the Robotic Palletizing automation Tapestry: A Symphony of Precision

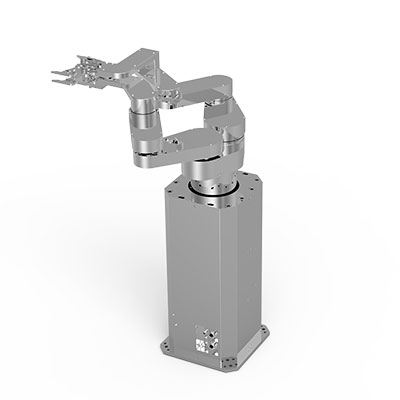

At the core of robotic palletizing automation efficiency lies the art of precision. Unlike manual palletizing, where human errors can lead to misaligned stacks and inefficiencies, robotic arms execute precise movements guided by advanced algorithms. These algorithms calculate the optimal placement of each item on the pallet, ensuring a tightly packed and stable load. The robotic symphony of precision orchestrates the seamless stacking of items, contributing to a more efficient use of space and resources.

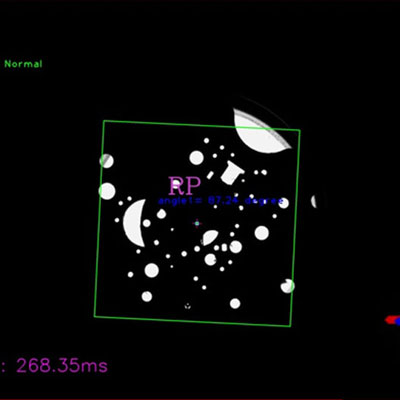

The depth of efficiency in robotic palletizing automation is further accentuated by the adaptability of robotic arms to handle varied shapes and sizes of products. Whether dealing with boxes, bags, or irregularly shaped items, robotic bag palletizer is equipped with advanced vision systems and sensing technologies that allow them to identify, pick, and place items with remarkable accuracy. This adaptability ensures that the palletization process remains efficient across a diverse range of products in dynamic manufacturing environments.

Harnessing Speed for Productivity: The Engine of Robotic Palletizing automation Efficiency

Efficiency in robotic palletizing is synonymous with speed. The rapid cycle times of robotic palletizers enable high-volume palletization, significantly outpacing manual alternatives. Robots made by industrial robot supplier can swiftly pick, place, and stack items with consistent speed and precision, leading to increased throughput and a reduction in overall production times. The seamless integration of speed into the palletization process marks a substantial leap forward in the efficiency of logistics and manufacturing operations.

The depth of efficiency in robotic palletizing automation is further highlighted by the real-time adaptability of these systems. In dynamic manufacturing environments where production demands may change rapidly, robotic palletizers can seamlessly adjust their speed and operations to accommodate varying requirements. This real-time responsiveness ensures that the palletization process remains efficient and agile, even in the face of unpredictable changes in production volumes or product mixes.

The Technological Nexus: Integrating Intelligence for Optimal Efficiency

Robotic palletizing automation efficiency reaches new heights through the integration of intelligent path planning and optimization algorithms. These algorithms analyze the layout of items, the available space on the pallet, and other variables to determine the most efficient stacking patterns. By optimizing the palletization path, robotic systems can achieve maximum density and stability, minimizing the number of pallets used and reducing transportation costs.

The depths of efficiency are further explored through data-driven decision-making processes. Robotic palletizing automation systems generate vast amounts of data during their operations, from cycle times to error rates. This data is then analyzed to identify areas for improvement, fine-tune algorithms, and optimize the overall efficiency of the palletization process. Continuous improvement driven by data insights ensures that robotic palletizing automation systems evolve and adapt to achieve peak performance.

In conclusion, the exploration of robotic palletizing automation efficiency takes us to the heart of technological innovation and precision. The symphony of precision, the engine of speed, and the technological nexus of intelligence converge to create a depth of efficiency that reshapes the landscape of palletization in logistics and manufacturing. As robotic palletizing automation systems continue to evolve, the depths of efficiency will deepen, paving the way for a future where precision, speed, and intelligent automation harmonize to optimize every aspect of the palletization process. The robotic journey into the depths of efficiency is not just a technological exploration; it's a transformative leap toward redefining the standards of productivity in the realm of modern supply chain dynamics.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur

(1).png)