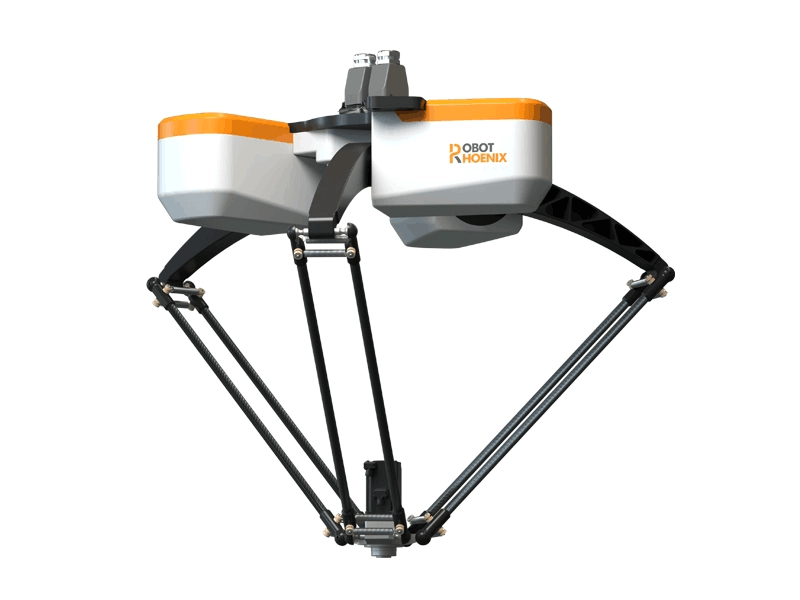

In the process of industrial automation upgrades, Robot Phoenix's four-axis SCARA robot has emerged as a key enabler for production line transformation across industries such as electronics, automotive, and consumer goods. With its advantages of high speed, high precision, and flexible deployment, it effectively replaces labor-intensive and repetitive tasks while adapting to complex processes with remarkable versatility.

From the low-damage handling of PAD glass panels to the assembly and welding of small automotive parts, and even the uniform gluing of curved speaker surfaces, the 4 axis SCARA robot from Robot Phoenix is precisely tailored to meet diverse process requirements. It addresses common manufacturing pain points such as damage to fragile materials, inconsistent process quality, and low manual efficiency—offering practical and scalable automation solutions across multiple sectors.

Electronics Industry: A Benchmark in Precision Operations

PAD Glass Panel Handling

Performs high-precision transfer tasks in fully automated cleaning lines, significantly reducing breakage rates and safely replacing high-risk manual operations.

Electronic Component Loading/Unloading

By integrating visual positioning and matrix tray systems, the robot enhances loading/unloading efficiency with high precision and stability for assembly lines.

Irregular Component Insertion on PCBs

Through flexible control and accurate gripping, it enables the standardized installation of non-standard components such as transformers.

Vision-Guided Gripping

Utilizes pneumatic grippers combined with machine vision systems to control cycle times under 5 seconds per pick—ideal for sorting and assembling irregular-shaped parts of various types.

Food and Pharmaceutical Industries: Ideal for High-Speed, Lightweight Operations

The four-axis SCARA robot, featuring translational motion on XYZ axes and rotational motion on the Z-axis, excels in industries like food and pharmaceuticals, especially when paired with high-precision vision systems. It is optimized for high-throughput tasks involving sorting, handling, and assembling lightweight, small, or bulk materials—ensuring both quality and efficiency. Applications for scara robots include automated boxing, pharmaceutical sorting, and packaging, all requiring precise and continuous operation.

The four-axis SCARA robot not only plays an irreplaceable role in traditional electronics manufacturing but is also unlocking new potential in fast-moving consumer goods, pharmaceutical, and food sectors. With its powerful flexibility and consistent repeatability, it is accelerating the transition to intelligent manufacturing across a wide range of industries.

Popular Search Insights into Automation Robotics

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur