When clients choose to purchase only the mechanical hardware of a delta robot, structural customization becomes essential. This article shares engineering strategies, real-world configurations, and integration lessons for maximizing performance and compatibility.

In the industrial robotics market, some clients—particularly integrators and OEMs—prefer to source only the mechanical portion of a delta robot and apply their own motion control systems. This approach provides greater system-level flexibility, but it also requires more precise planning on the mechanical side.

Unlike fully integrated robots, hardware-only delta robots must support clear interface definitions, reliable kinematic behavior, and application-specific structural performance. As one of the leading industrial robot manufacturers, Robotphoenix has responded to this demand by designing a variety of customizable hardware solutions. Below are two typical examples.

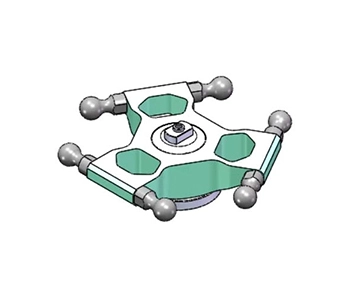

Heavy-Payload Delta Robot: Replacing Springs with Hooke’s Joint

To address client needs for higher load capacity, we modified the standard delta robot structure. Specifically, we replaced the conventional ball-cup and spring joint with a Hooke’s joint system.

This change resulted in a significant increase in payload capacity—from 3 kg to 15 kg—without changing the arm span. It also reduced the number of fatigue-prone components by removing the spring mechanism.

However, the updated structure comes with trade-offs. Disassembly and maintenance are more complex, and production costs are higher due to the need for tighter machining tolerances. For clients in heavy packaging or metal handling industries, the benefits often outweigh the drawbacks, but the structure must be carefully evaluated before adoption.

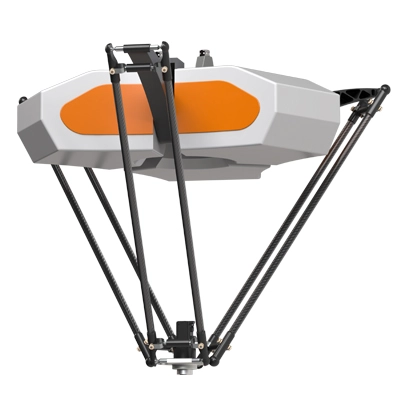

Carbon Fiber Delta Robot: A Lightweight High-Speed Configuration

In high-speed applications where speed, efficiency, and energy consumption are key priorities, we have delivered delta pick and place robot series with key structural components—such as the upper arms and moving platforms—made entirely of carbon fiber.

This material significantly reduces the mass of the robot’s moving parts. As a result, the system operates faster, consumes less energy, and achieves better precision under dynamic conditions.

The main downside of this configuration is cost. Carbon fiber components are more expensive to source and require specialized production processes. This structure is therefore best suited to industries like food sorting, pharmaceutical packaging, or consumer electronics where cycle time and throughput are critical.

Key Takeaways: Considerations for Hardware-Only Delta Robot Projects

From these and other cases, we have developed a clear set of expectations for delta robot hardware customization projects:

Define mechanical structure in detail at an early stage

The client’s control system must be compatible with the robot’s joint geometry, kinematic model, and load distribution. Early sharing of 3D models, joint drawings, and mechanical specifications is essential.

Do not rely solely on previous experience

While past solutions can serve as references, each application scenario must be evaluated independently. For example, a joint system suitable for light food handling may not perform well in heavy logistics.

Support configuration should match functional goals

Carbon fiber arms may offer performance advantages but are not cost-effective for all projects. Conversely, high-payload Hooke’s joint structures may introduce complexity that is unnecessary for lightweight products.

Ensure manufacturing traceability and service support

Even when only the hardware is delivered, future maintenance and upgrades depend on version-controlled BOMs and structural records. Documentation must include not just drawings, but also material data, stress limits, and replacement part plans.

Maintain clear technical communication between teams

The person designing the hardware must also be involved in technical discussions with the client’s engineering team. This reduces the risk of misalignment between the physical robot and the control logic.

This kind of structural flexibility reflects a broader trend in the robotics industry—toward open, modular, and integrator-friendly systems. For clients seeking only delta robot hardware, we aim to offer not just components, but complete engineering support to ensure smooth integration and stable long-term operation.

If you are currently evaluating hardware options or facing challenges in integrating a third-party control system with delta robot hardware, we welcome discussion. Your questions and insights may contribute to further improvement in our mechanical platform designs.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur