In the rapidly evolving landscape of industrial automation, packaging robots have emerged as game-changers, revolutionizing the way products are packaged, sorted, and shipped. These versatile machines are reshaping the packaging industry, leading to increased efficiency, reduced labor costs, and improved overall productivity. In this blog, we will delve into the various aspects of the packaging robots market and explore its impact on the manufacturing sector.

Growing Demand and Packaging Robots Market Overview

The packaging robots market has witnessed unprecedented growth in recent years. As companies strive for increased production volumes while maintaining consistent quality, they are turning to automation to achieve their goals. The global market for packaging robots is experiencing a surge, with a compound annual growth rate (CAGR) projected to be over 12% between 2021 and 2026. The market's estimated value is expected to reach several billion dollars by the end of the forecast period.

Types of Packaging Robots

Packaging robots come in a wide variety of types, each designed to cater to specific packaging needs. Some of the most common types include:

Pick-and-Place Robots: These robots excel at handling and placing products into packaging containers with precision and speed. They are often used in the food and beverage, pharmaceutical, and consumer goods industries.

3-Axis Pick And Place Robot

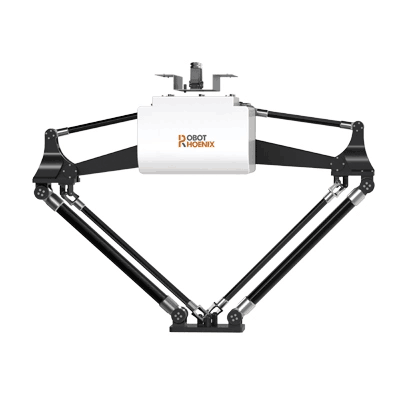

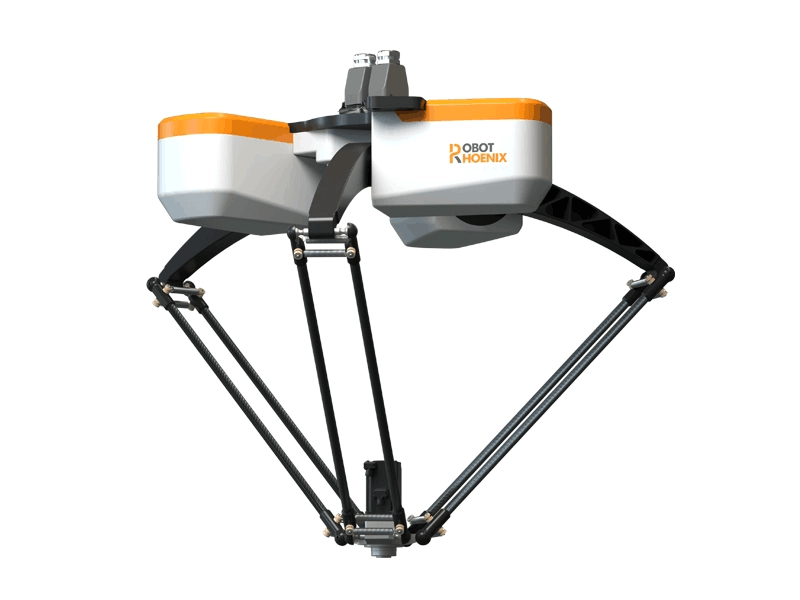

Delta Robot Pick And Place

Industrial Pick And Place Robot

Scara Robot Pick And Place

Palletizing Robot Price

Cartoning Robots: Cartoning robots automate the process of placing products into cartons, boxes, or blister packs, ensuring uniformity and speed in the packaging process.

Key Advantages of Packaging Robots

The increasing adoption of packaging robots can be attributed to several compelling advantages they offer to manufacturers:

Enhanced Efficiency: With advanced robotic packaging systems, packaging robots work tirelessly, 24/7, without experiencing fatigue or slowing down. This results in a significant increase in overall production efficiency, leading to faster order fulfillment.

Cost Savings: Although the initial investment in packaging robots can be substantial, the long-term cost savings are undeniable. Reduced labor costs, lower error rates, and optimized use of resources lead to improved profit margins.

Technological Innovations Driving the Market

The packaging robots market owes its rapid growth to continuous technological advancements. Some of the key innovations shaping the industry include:

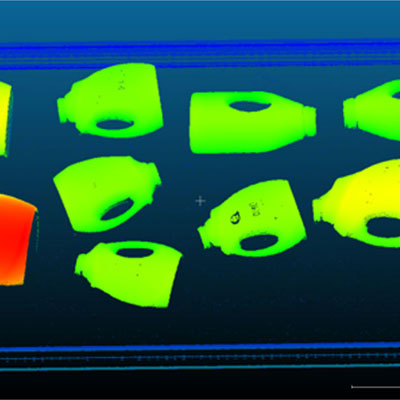

Vision Systems: Integration of advanced vision systems allows packaging robots to recognize and handle objects of different shapes, sizes, and colors, ensuring accurate and reliable picking and packing.

Collaborative Robots (Cobots): Collaborative robots work alongside human workers, creating a safer and more efficient work environment. They can take over repetitive tasks while leaving complex decision-making to human operators.

6-Axis Collaborative Robot

Collaborative Scara Robot

Artificial Intelligence (AI): AI-powered packaging robots can adapt their operations based on real-time data, optimizing performance and increasing productivity. Machine learning algorithms also enable them to improve their efficiency over time.

Internet of Things (IoT) Connectivity: IoT integration enables packaging robots to communicate with other machines, systems, and databases. This interconnectedness streamlines the packaging process and provides valuable data for analysis and decision-making.

Challenges and Future Outlook

Despite their numerous advantages, the packaging robots market also faces certain challenges:

In conclusion, the packaging robots market is a dynamic and rapidly expanding sector within the realm of industrial automation. With their unmatched precision, speed, and versatility, packaging robots are transforming the packaging industry and shaping the future of manufacturing. As technology continues to evolve, we can expect even more innovative advancements in the field, propelling the market to new heights and benefiting manufacturers worldwide.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur