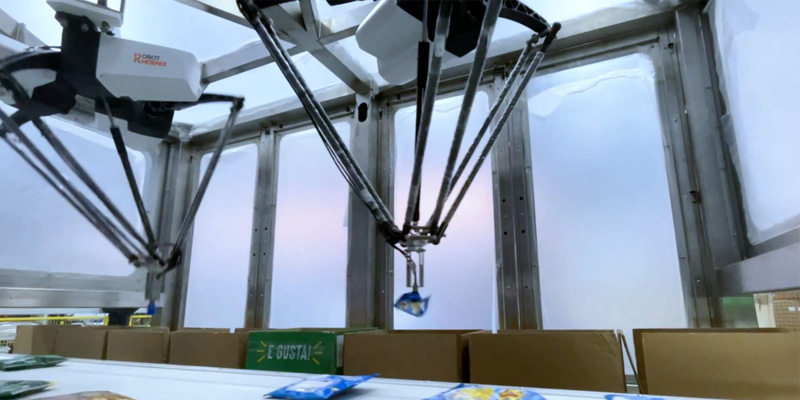

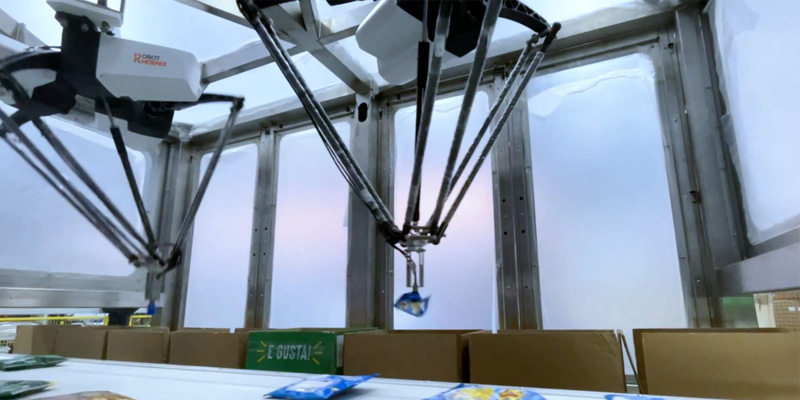

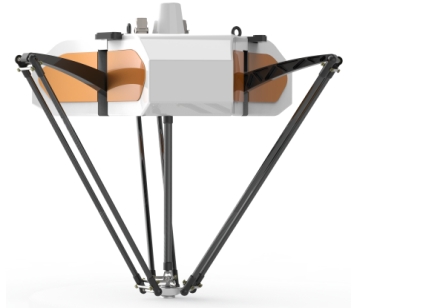

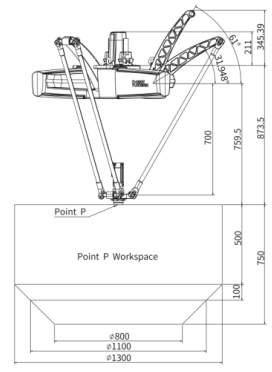

Our Delta and SCARA robots are designed to seamlessly integrate into different stages of the customer’s packaging production line, delivering speed, precision, and flexibility. Whether it’s primary packaging (placing products into trays or pouches) or secondary packaging (cartoning, case packing), our robots ensure efficient and reliable operations. We specialize in automation robotic packaging and provide advanced robotic packaging solutions tailored to meet diverse industry needs.

How Our Robots Work on Packaging Lines

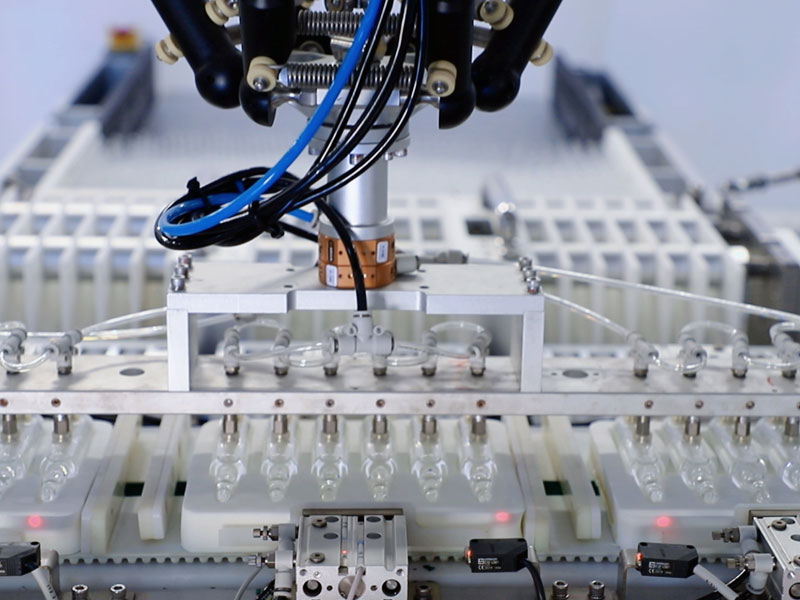

Infeed & Sorting – Pick, sort, and align products directly from conveyors for smooth downstream packaging.

Primary Packaging – Place bakery, confectionery, dairy, or snack products into trays, boxes, or flow-wrappers with consistent accuracy.

Secondary Packaging – Load packaged items into cartons, cases, or multipacks, ready for transport.

Customer Benefits

Seamless integration into existing or new production lines.

Reduced labor intensity, helping address labor shortages and rising costs.

Safer operations by eliminating exposure to harmful or fatiguing packing tasks.

Consistent product quality, ensuring every package meets strict hygiene and packaging standards.

Scalable and high throughput, supporting large-volume production without compromising accuracy.

Flexible adaptation to different product specifications and packaging formats.

As a specialized robot manufacturing company, Robotphoenix delivers customized automation robotic packaging systems designed to maximize productivity, reduce costs, and comply with stringent quality and safety regulations throughout the entire packaging line. We are also a trusted robot OEM partner, offering reliable and innovative automation solutions.

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur

(1).png)