In today's fast-paced and ever-changing industrial landscape, industries are increasingly turning towards technology to enhance their efficiency, productivity, and profitability. And one of the technologies that are powering this transformation is the industrial robot software. From manufacturing to logistics to agriculture, industrial robot software has become an essential tool for industrial automation. In this blog, we will explore the key features and functions of industrial robot software.

What is Industrial Robot Software?

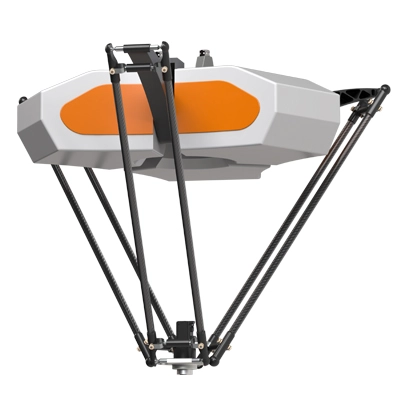

Before delving into the key features and functions of industrial robot software, it is essential to define what it is. Industrial robot software refers to the programs, applications, and operating systems that are designed to control and operate industrial robots. Industrial robots are programmable machines that automate tasks in manufacturing, assembly, and production lines. Industrial robot software enables users to program and control these robots to perform specific tasks.

Key Features of Industrial Robot Software

Now let's explore the key features of industrial robot software:

Programming Flexibility: Industrial robot software provides programming flexibility, enabling users to create and customize robot programs to suit their specific needs. This flexibility allows for greater control over the robot's movements, speed, and accuracy.

User-Friendly Interface: Advanced industrial robotics software comes with a user-friendly interface that simplifies the programming process. With drag-and-drop functionalities, users can create robot programs easily, reducing the learning curve and training time for new users.

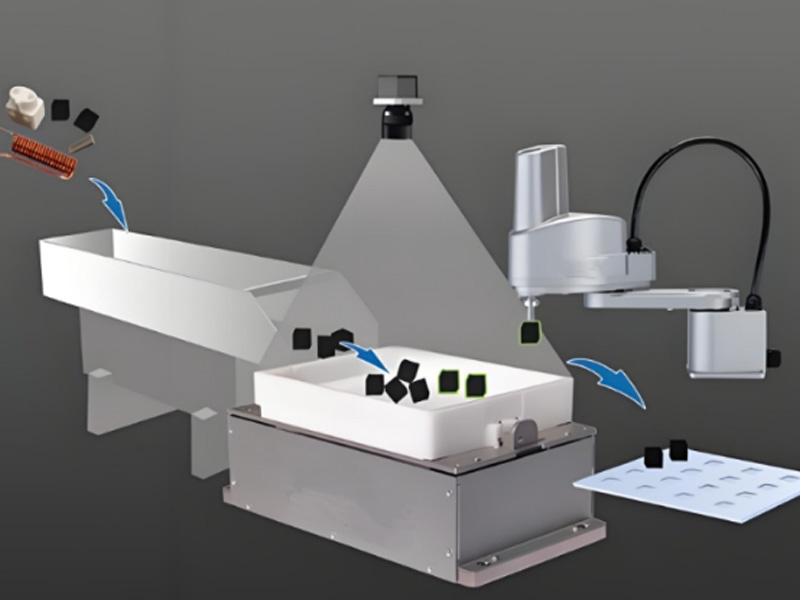

Integration with Other Systems: Industrial robot software is designed to integrate seamlessly with other automation systems, such as programmable logic controllers (PLCs) and computer numerical control (CNC) machines. This integration ensures a smooth flow of data and communication between the different automation systems.

Simulations and Visualization: Industrial robot software includes simulation and visualization tools that enable users to simulate robot movements and program flows. This feature helps users to identify and eliminate potential errors before the actual process execution, thus reducing downtime and enhancing the quality of the final product.

Functions of Industrial Robot Software

Now that we have explored the key features of industrial robot software, let's look at the main functions of this technology:

Robot Programming: Industrial robot software developed by industrial robot supplier enables users to program and customize robot movements, actions, and parameters to automate tasks.

Motion Control: Industrial robot software enables users to control the robot's precise movements and speeds, enabling safe and efficient operations.

Data Collection and Analysis: Industrial robot software collects, analyzes, and provides data and reports on the robot's performance, enabling users to optimize processes and evaluate the effectiveness of the automation system.

Visualization and Simulation: Industrial robot software provides visualization and simulation tools that enable users to identify and eliminate potential errors before the actual process execution, thus reducing downtime and enhancing the quality of the final product.

Industrial robot software is an essential tool for automation in industries. The key features and functions of industrial robot software, such as programming flexibility, user-friendly interface, integration with other systems, simulation, and visualization tools, enable industries to automate their processes efficiently, effectively, and safely. As technology continues to evolve, industrial robot software will remain a vital component of industrial automation.

Essential Knowledge of Industrial Robotic Automation

Learn More

Learn More

EN

EN  ja

ja  ko

ko  fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  ur

ur